Solenoid Reversing Valve

1 Excellent switching characteristics, high-frequency operation, smooth and gentle switching process, effectively reduce vibration and shock in the system, insensitive to low voltage, short-term overvoltage, overload, and mechanical tightness, expand the applicable power supply range, enhance system design flexibility, simplify electrical control lines, simplify system design and maintenance.

2 It can ensure the stable operation of the system under complex working conditions.The switching process of this valve is smooth and gentle, which effectively reduces the vibration and shock in the system, and is extremely beneficial to the long-term operation of the equipment.Even when the armature stays in a certain position of the electromagnet, it will not cause any danger to the coil. This feature is especially suitable for applications under complex operating conditions.

3the electromagnetic directional control valve is insensitive to low voltage, short-term overvoltage, overload, and mechanical clamping. This characteristic ensures the stable operation of the system.The valve can use a power supply through a rectifier, which further expands the range of applicable power supplies and enhances the flexibility of system design.According to different application needs, the electromagnetic directional control valve is also specially equipped with AC magnets, and its electrical control circuit is simple, simplifying the design and maintenance of the overall system.

1. Control the pressure of the hydraulic system

The hydraulic control valve can change the pressure and stability of the hydraulic system by adjusting the opening size and opening method in the valve core, so as to meet the work needs of different pressure requirements.

2. Control the flow of the hydraulic system

The hydraulic control valve can control the flow of fluid by adjusting the size and opening method of the opening in the spool, so that the flow rate and flow rate in the hydraulic system can meet the needs of the working mechanism for hydraulic power.

3. Control the direction of the hydraulic system

The hydraulic control valve can control the flow direction of the liquid, so that the liquid in the hydraulic system flows to a specific position of the working mechanism, and realize various actions of the working mechanism.

4. Protect the hydraulic system and working mechanism

The hydraulic control valve can improve the reliability and safety of the hydraulic system by setting up protective measures such as hydraulic buffer circuits and relief valves, while protecting the working mechanism from abnormal overload and operation interference damage.

5. Improve the degree of automation of the hydraulic system

Hydraulic control valves can be used in conjunction with electrical control, etc., to realize various complex automation processes in industrial automation production lines, improve production efficiency and quality, and reduce labor investment.

DE6 electromagnetic directional control valve: the diameter is 6, the working pressure can reach 31.5MPa, and the flow rate can reach 80L/min.It uses a direct-acting electromagnet to operate a directional spool valve as the standard type 1.

Wiggs electromagnetic directional control valve: The basic component of automation used to control fluids, not limited to hydraulic or pneumatic systems.It has the characteristics of high reliability, wide applicability, multiple operating methods, fast response, safety and reliability.The use of high-quality materials and advanced manufacturing technology to ensure its high reliability and long life

The working principle of hydraulic electromagnetic reversing valve is mainly to control the position of the spool valve through the energization and loss of power of the electromagnet, thereby changing the direction of oil flow.When the electromagnet is energized, the magnetic field generated attracts the spool valve to move and turns on the circuit; when the electromagnet loses power, the spring force causes the spool valve to return, changing the direction of oil flow and realizing the change of direction of movement.The hydraulic electromagnetic reversing valve consists of a valve body, a valve core, a push rod and an electromagnetic coil. After the electromagnetic coil is energized, a magnetic force is generated, which pushes the push rod to change the position of the valve core.By controlling the current on-off of the electromagnetic coil, the on-off of the oil circuit of the hydraulic system and the direction of movement of the oil can be controlled.This kind of valve is a control element in the hydraulic system. It can change the on-off and flow direction of the oil. It is widely used in the control of mechanical devices such as cylinders and motors, and realizes the electrical control of mechanical movement.

Product scenario application

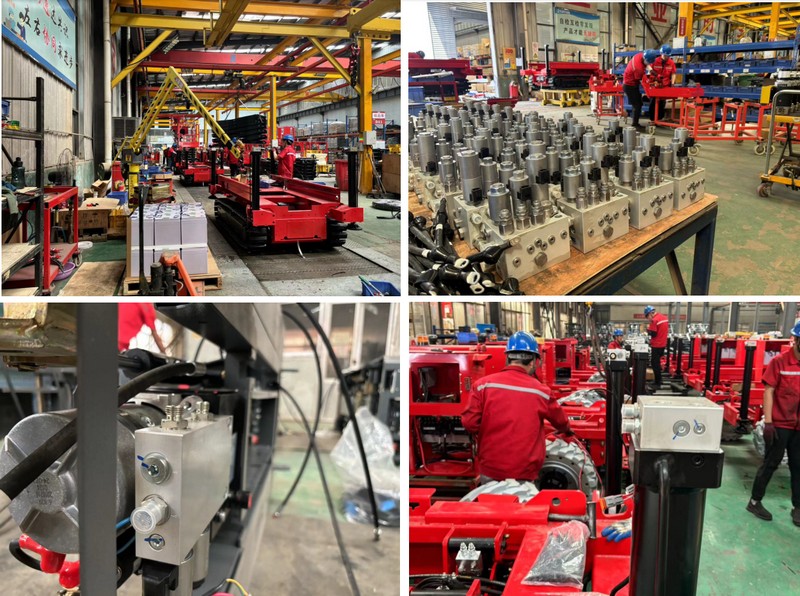

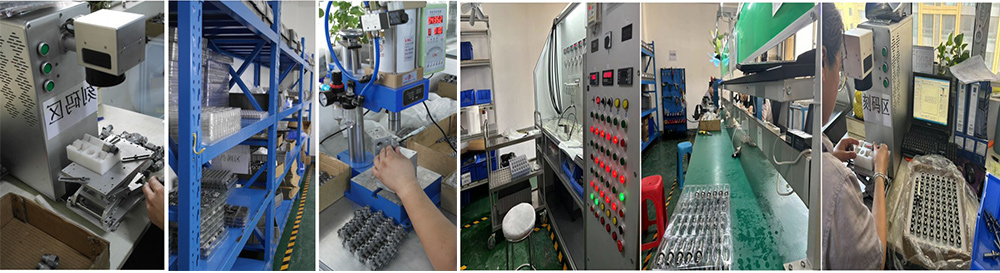

Product Line:

The production line for Customised Hydraulic Valve Blocks is characterised by precise craftsmanship and efficient processes, ensuring that each block is perfectly tailored to the customer's individual requirements. The production line begins with the initial design, which is planned in detail by engineers according to the customer's requirements, followed by material processing and precision manufacturing on high-precision machinery and equipment. After a rigorous assembly and testing process, each valve block is strictly inspected to ensure its performance and durability.

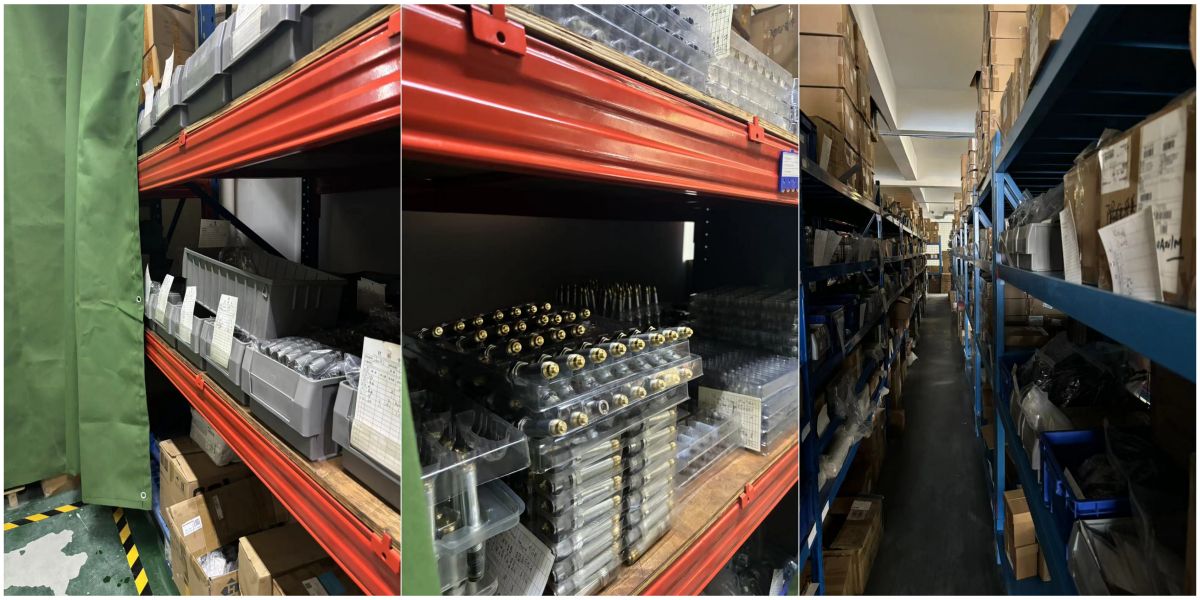

Warehouse:

The facility for producing Customized Hydraulic Valve Blocks is a state-of-the-art manufacturing plant designed for precision and efficiency. The plant features advanced CNC machining centers that ensure high accuracy in cutting, drilling, and milling. Dedicated design and engineering teams work closely to tailor each valve block to meet specific client requirements. The production process includes rigorous assembly and testing stations, where each valve block undergoes thorough quality checks to ensure optimal performance and reliability. The facility also incorporates modern surface treatment and packaging areas, ensuring that the final products are well-protected and ready for prompt delivery to clients.

Packing&transportation:

The packaging for Customized Hydraulic Valve Blocks is meticulously designed to ensure safe and secure transport. Each valve block is carefully wrapped in protective materials, such as foam or bubble wrap, to guard against potential damage during shipping. The blocks are then placed in custom-sized, reinforced boxes that provide additional cushioning and support. Each package is clearly labeled with handling instructions and product information to facilitate smooth logistics and tracking. This comprehensive packaging approach ensures that the valve blocks arrive at their destination in excellent condition, ready for installation and use.