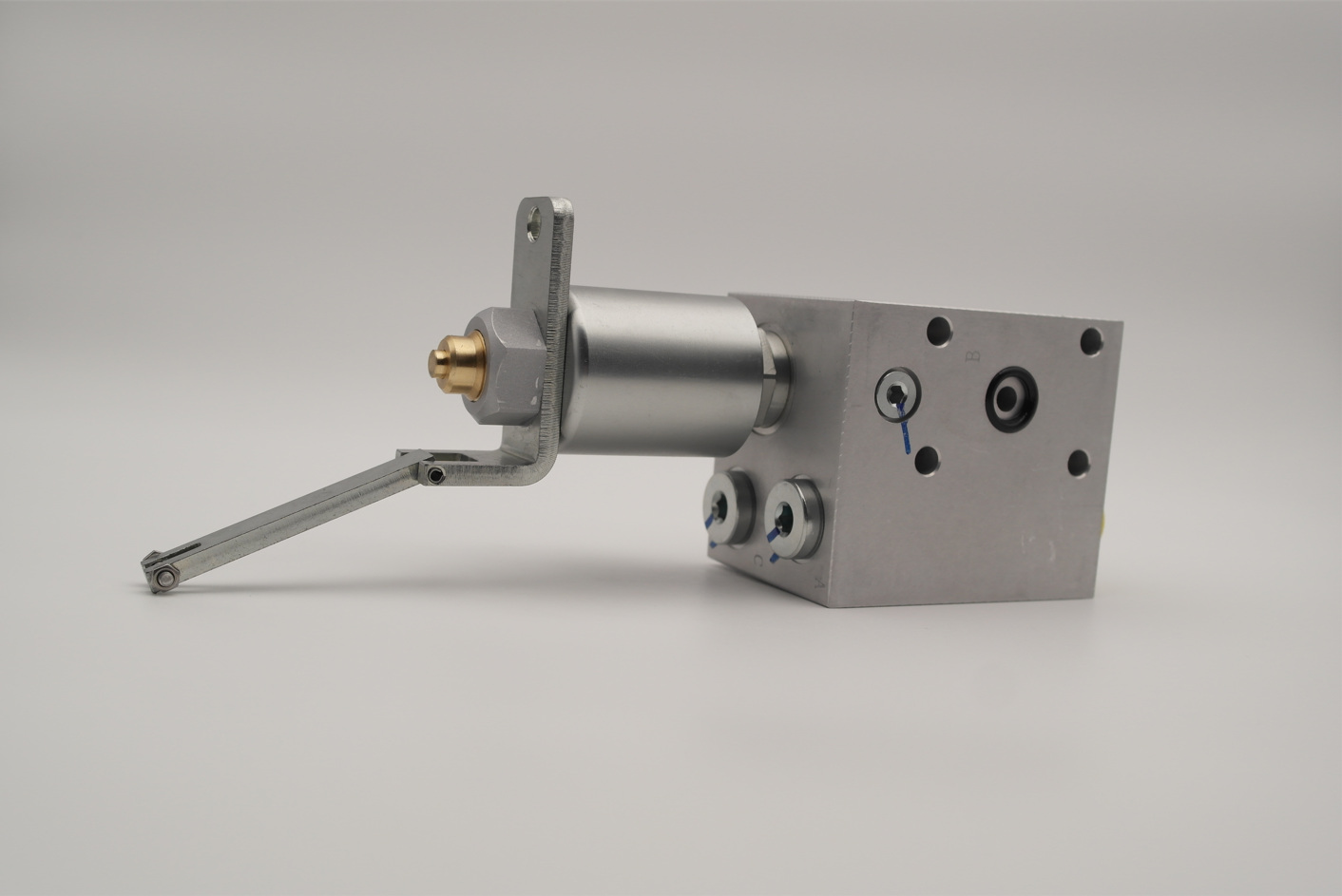

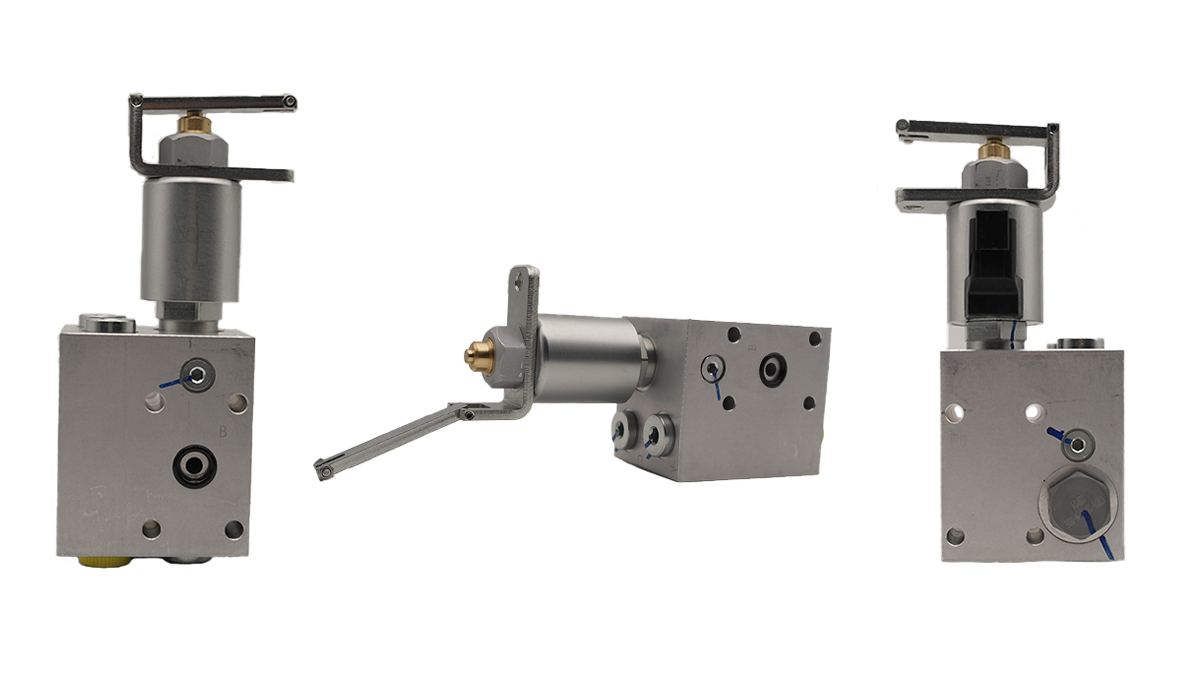

Lower Lifting Hydraulic Valve

1 Excellent materials: The products are made of excellent materials to ensure the quality and durability of the products.

2 Aging resistance: The product has good aging resistance and can maintain stable performance in various environments.

3 Long service life: Due to the excellent materials and fine craftsmanship, the service life of the product has been significantly improved.

4 Acid and alkali resistance: The product has been treated with nickel, which has the characteristics of acid and alkali resistance, and is suitable for various harsh working environments.

5 Customizable: According to customer needs, products can be customized to meet the needs of different customers.

These advantages make the lower lifting hydraulic valve e a popular product in the market, and it is widely used in construction machinery, metallurgy, industry, petroleum, machine tool equipment, electric power, agricultural machinery, pile bridges and other fields.

Lower lifting hydraulic valve

Detailed parameters

| Rated pressure | Rated flow | Voltage | material | opening pressure |

| 240bar | 20L/min | DC24V±10%; plug type DTO4-2P | Valve body material aluminum alloy, surface anodized | 0.5 bar |

The hydraulic valve is a key component in the hydraulic system. It controls the lifting movement of the hydraulic cylinder by controlling the flow direction of the hydraulic oil.Specifically, when an object needs to be lowered, the hydraulic valve will control the flow of hydraulic oil from one side of the hydraulic cylinder back to the other side of the hydraulic cylinder, so that the piston of the hydraulic cylinder moves downwards to achieve the object's descent.This process is achieved by operating a hydraulic valve. The hydraulic valve changes the flow path of the hydraulic oil, causing the pressure inside the hydraulic cylinder to change, which in turn drives the piston to move.

The core components of the hydraulic system include hydraulic pumps, hydraulic cylinders, control valves and hydraulic fuel tanks.When the hydraulic lift is started, the hydraulic pump starts to work, and the hydraulic oil is extracted from the fuel tank and pressed into the hydraulic cylinder through rotational movement.The hydraulic pump presses the hydraulic oil into the hydraulic cylinder to generate pressure, which is transmitted to the piston of the hydraulic cylinder through the hydraulic pipeline.The control valve controls the lifting movement of the hydraulic cylinder by controlling the flow direction of the hydraulic oil.When an object needs to be lowered, the control valve will adjust the flow direction of the hydraulic oil, causing the pressure inside the hydraulic cylinder to change, and then drive the piston to move downwards to achieve the object's descent.

Throughout the process, the hydraulic oil is continuously recycled between the hydraulic pump, the hydraulic cylinder and the control valve.When the hydraulic pump pressure no longer provides hydraulic oil, the hydraulic oil will be returned to the hydraulic tank for the next use.Through the conversion and control of hydraulic pressure, the hydraulic lift can realize the smooth lifting of objects. It has the characteristics of large load-bearing capacity, adjustable lifting speed, and easy operation. It is widely used in various fields.

Application Scenarios:

Our customized hydraulic valve blocks represent the top level of hydraulic control technology, designed with a focus on performance, reliability and durability. Their wide range of application scenarios make them ideal for use in a variety of mechanical equipment and industrial systems.

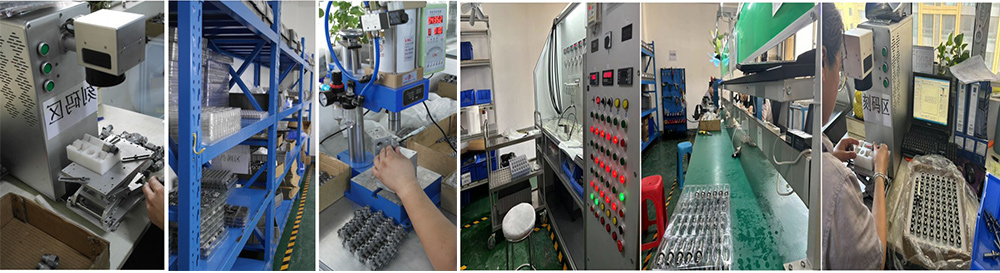

Product Line:

The production line for Customised Hydraulic Valve Blocks is characterised by precise craftsmanship and efficient processes, ensuring that each block is perfectly tailored to the customer's individual requirements. The production line begins with the initial design, which is planned in detail by engineers according to the customer's requirements, followed by material processing and precision manufacturing on high-precision machinery and equipment. After a rigorous assembly and testing process, each valve block is strictly inspected to ensure its performance and durability.

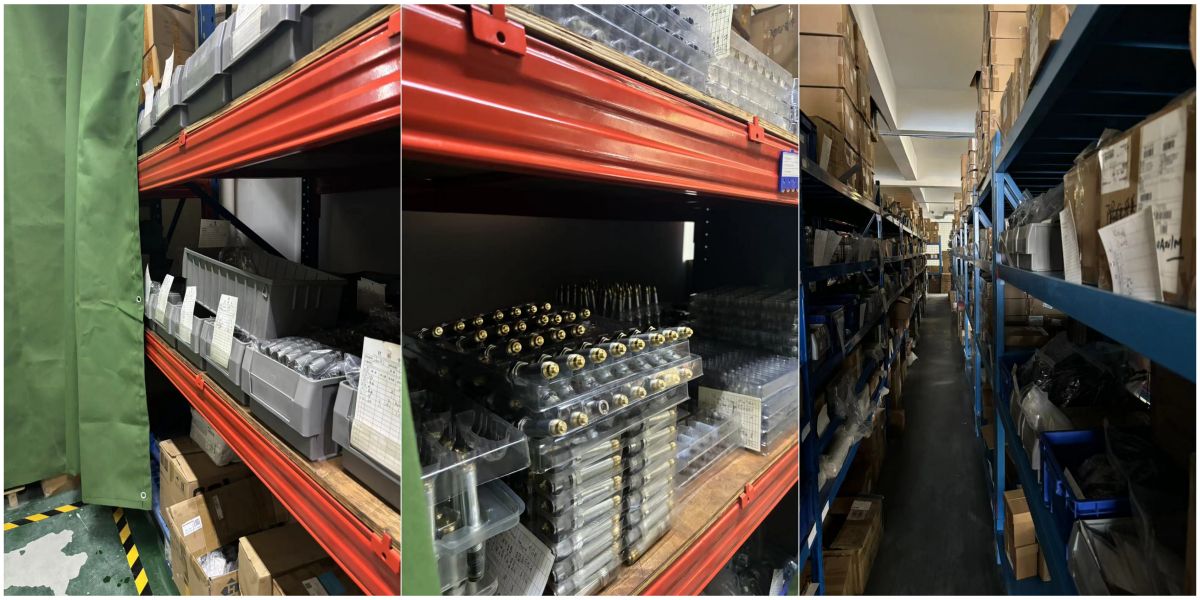

Warehouse:

The facility for producing Customized Hydraulic Valve Blocks is a state-of-the-art manufacturing plant designed for precision and efficiency. The plant features advanced CNC machining centers that ensure high accuracy in cutting, drilling, and milling. Dedicated design and engineering teams work closely to tailor each valve block to meet specific client requirements. The production process includes rigorous assembly and testing stations, where each valve block undergoes thorough quality checks to ensure optimal performance and reliability. The facility also incorporates modern surface treatment and packaging areas, ensuring that the final products are well-protected and ready for prompt delivery to clients.

Packing&transportation:

The packaging for Customized Hydraulic Valve Blocks is meticulously designed to ensure safe and secure transport. Each valve block is carefully wrapped in protective materials, such as foam or bubble wrap, to guard against potential damage during shipping. The blocks are then placed in custom-sized, reinforced boxes that provide additional cushioning and support. Each package is clearly labeled with handling instructions and product information to facilitate smooth logistics and tracking. This comprehensive packaging approach ensures that the valve blocks arrive at their destination in excellent condition, ready for installation and use.

Related News

Submitted successfully

We will contact you as soon as possible