Hydraulic Control Valve Set

1、Reliability: Reusable throughout the product's lifespan with minimal maintenance.

2、Durability: The hydraulic block's force is nearly unlimited, with a strong driving force over 350KN. Standard models operate between -20°C and 120°C, offering cleanliness and high energy efficiency.

3、Widely Used: Cylinder synchronous valves provide precise control, reliability, and stability. Made from high-quality materials and precision technology, they perform well in harsh environments.

4、Customization: Can be tailored to meet specific needs, making them versatile for various mechanical devices.

1. The concept of hydraulic control valve

Hydraulic control valve refers to a valve used to control and adjust the pressure, flow, direction and other parameters in the hydraulic system.It can play different roles according to actual needs, including four ways of pressing force control, flow control, direction control and combination control.

Second, the working principle of the hydraulic control valve

The working principle of the hydraulic control valve is based on the principle of fluid mechanics.When the fluid in the hydraulic control valve flows, the fluid is hindered by the valve core and resistance occurs, and the valve core then moves accordingly.In this way, a pressure difference will be generated in each hole between the valve core and the valve body, so as to realize the adjustment of the hydraulic control valve.

The hydraulic control valve is mainly composed of the valve body, valve core, spring, sealing ring and other parts.Its working principle is that the inlet pressure is instantly applied to the valve core, causing the valve core to move by force, thereby changing the area and position of the valve port, causing the flow rate or pressure to change.

Third, the application of hydraulic control valve

Hydraulic control valves are widely used in industry, agriculture and transportation, and are one of the essential components in hydraulic systems.In the industrial field, the main role of hydraulic control valves is to control and regulate the movement of various mechanical components, such as the control of hydraulic cylinders, motors, valves and other equipment.In the agricultural field, hydraulic control valves are mainly used in the hydraulic systems of agricultural machinery such as tractors and combine harvesters.In the transportation field, some large-scale machinery and equipment, such as cranes and excavators, require the use of hydraulic control valves.

Product application

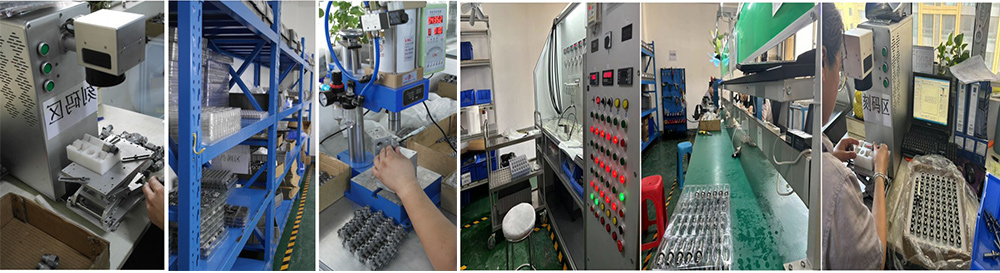

Product Line:

The production line for Customised Hydraulic Valve Blocks is characterised by precise craftsmanship and efficient processes, ensuring that each block is perfectly tailored to the customer's individual requirements. The production line begins with the initial design, which is planned in detail by engineers according to the customer's requirements, followed by material processing and precision manufacturing on high-precision machinery and equipment. After a rigorous assembly and testing process, each valve block is strictly inspected to ensure its performance and durability.

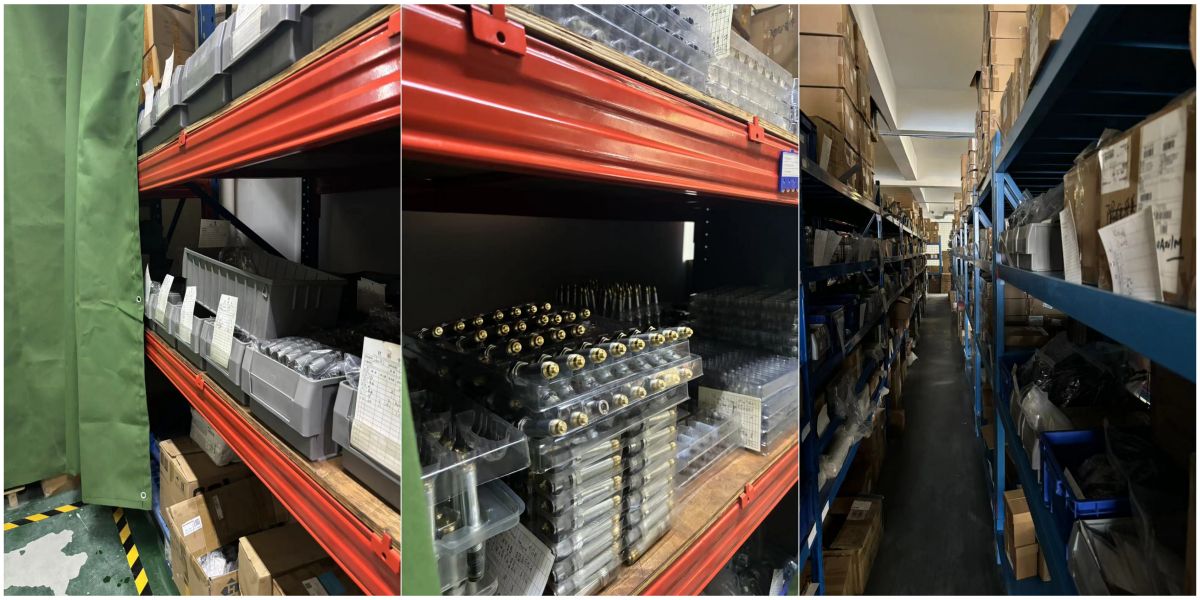

Warehouse:

The facility for producing Customized Hydraulic Valve Blocks is a state-of-the-art manufacturing plant designed for precision and efficiency. The plant features advanced CNC machining centers that ensure high accuracy in cutting, drilling, and milling. Dedicated design and engineering teams work closely to tailor each valve block to meet specific client requirements. The production process includes rigorous assembly and testing stations, where each valve block undergoes thorough quality checks to ensure optimal performance and reliability. The facility also incorporates modern surface treatment and packaging areas, ensuring that the final products are well-protected and ready for prompt delivery to clients.

Packing&transportation:

The packaging for Customized Hydraulic Valve Blocks is meticulously designed to ensure safe and secure transport. Each valve block is carefully wrapped in protective materials, such as foam or bubble wrap, to guard against potential damage during shipping. The blocks are then placed in custom-sized, reinforced boxes that provide additional cushioning and support. Each package is clearly labeled with handling instructions and product information to facilitate smooth logistics and tracking. This comprehensive packaging approach ensures that the valve blocks arrive at their destination in excellent condition, ready for installation and use.