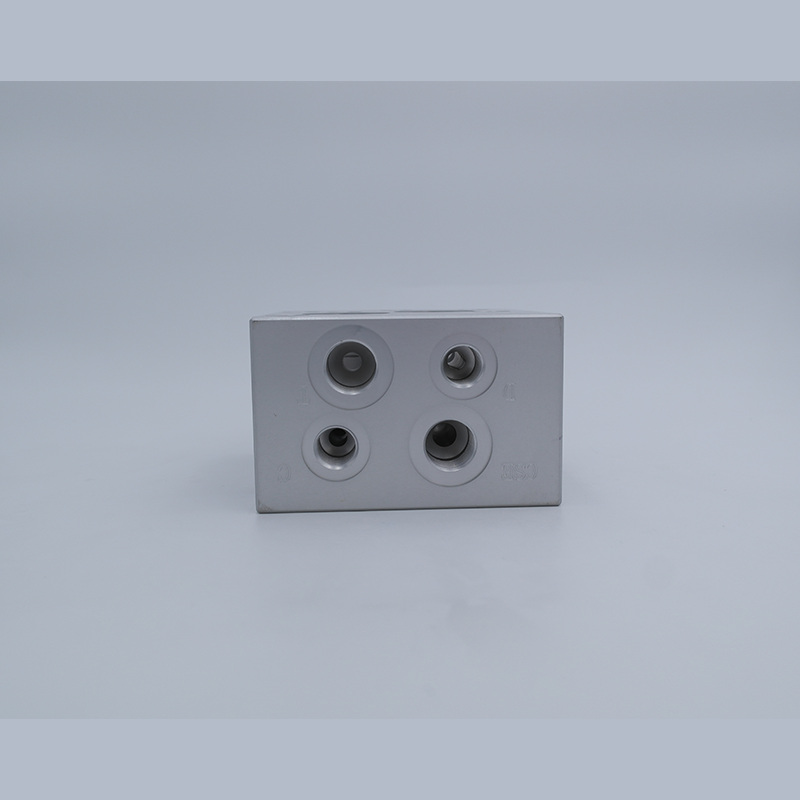

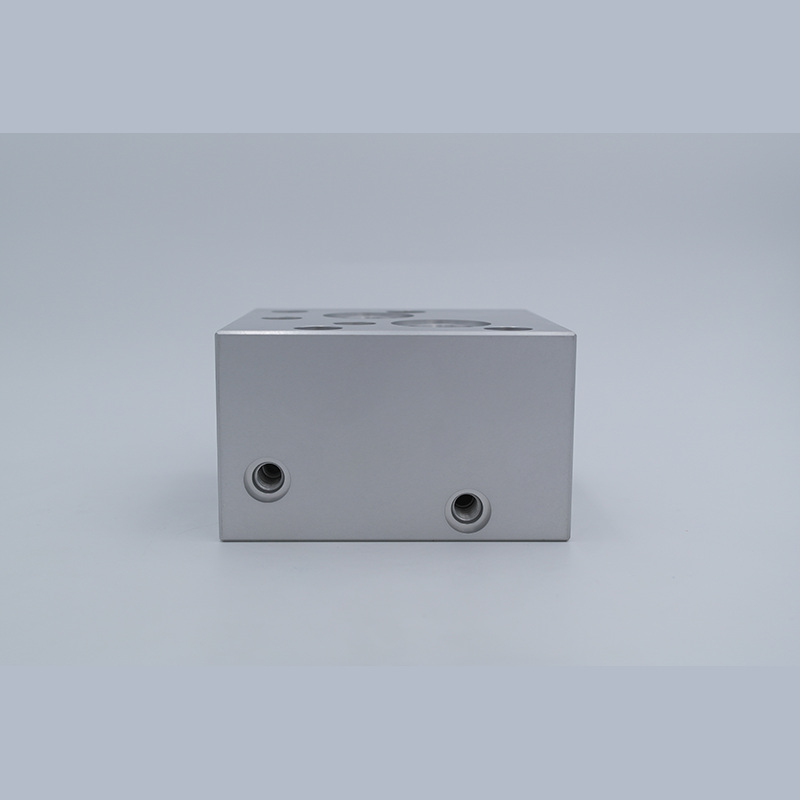

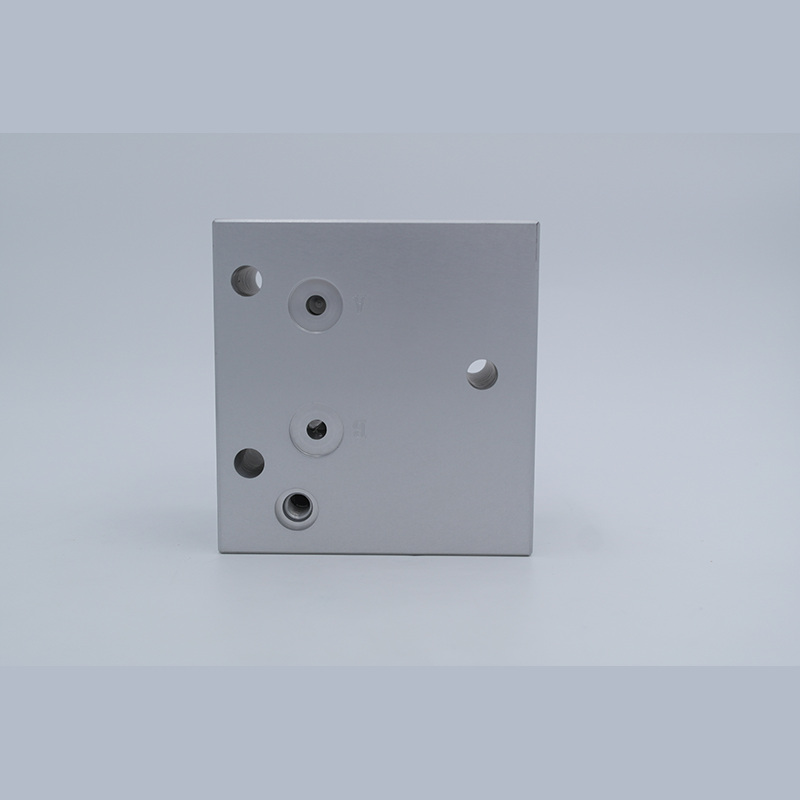

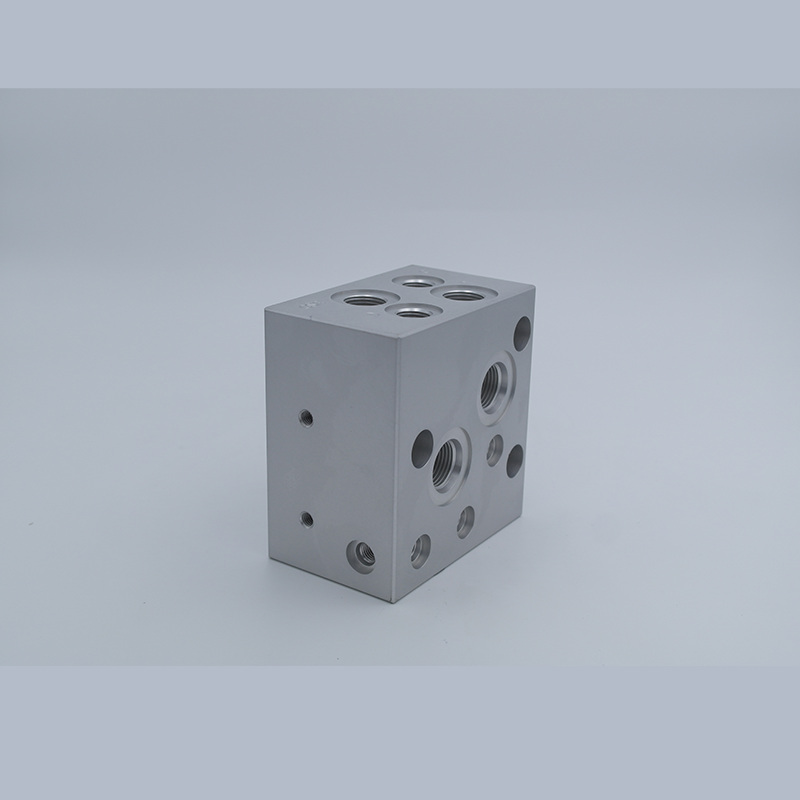

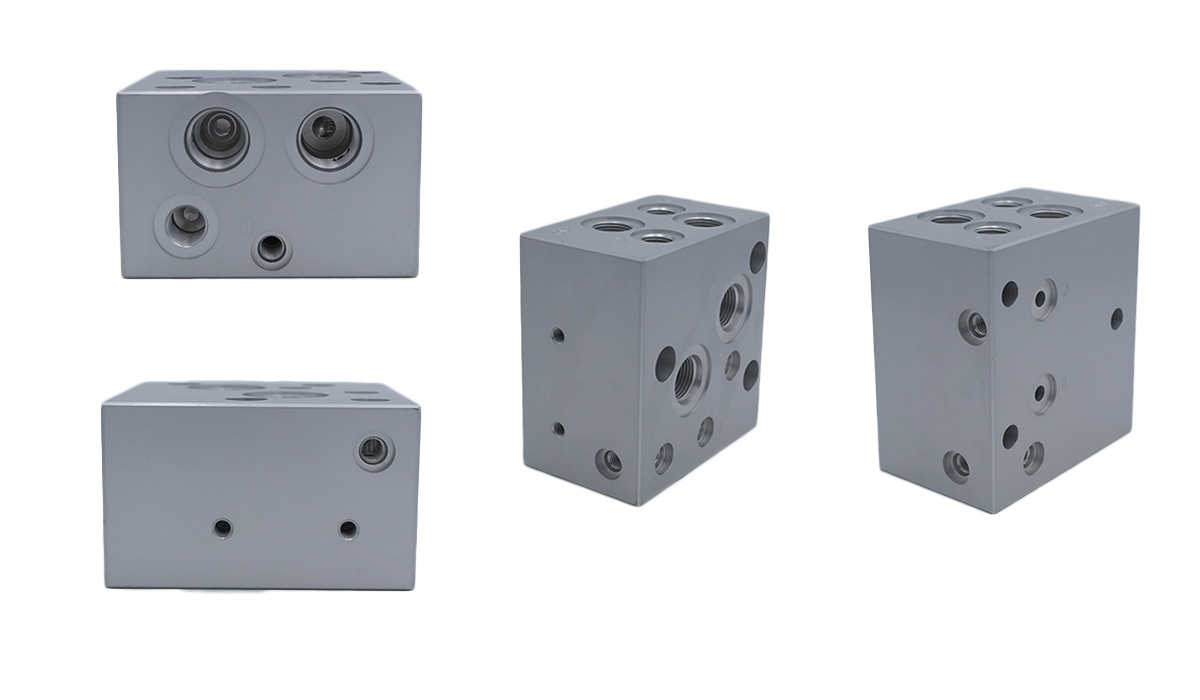

HIC2 Type Hydraulic Valve Block

Compact design: The integration of multiple hydraulic valves into one block reduces the length and number of connecting pipelines, thereby reducing leakage points and installation space.

High reliability: due to the reduction of the number of connecting pipelines and joints, potential leakage points are reduced, and the reliability of the system is improved.

Easy maintenance: The modular design makes it easier to maintain and replace hydraulic valves and reduces downtime.

Cost-effectiveness: By reducing the number of pipelines and joints, material costs and installation costs are reduced.

High flexibility: the design can be customized according to specific application needs to meet the requirements of different working conditions

HIC2 Type Hydraulic valve block

It is an important part of the hydraulic system. It has many functions, including the following points:

1. Control the flow of liquid

The Hydraulic Valve block can control the flow direction of the liquid so that the liquid can flow to the desired part.For example, the flow of pressure oil to the hydraulic cylinder enables it to move, or the flow of liquid to the hydraulic motor enables it to drive mechanical movement.

2. Control the flow of liquid

The hydraulic valve block can control the flow rate of the liquid so that it can reach the required flow rate.Can meet the needs of various flow rates, such as the start and stop of the machine, the execution of various processes, etc.

3. Control the pressure of the liquid

The hydraulic valve block can control the pressure of the liquid and allow the hydraulic system to operate under the required pressure, such as the hydraulic control system in a machine tool.

4. Control the direction of the liquid

The hydraulic valve block can control the direction of the liquid and make it run in the desired direction.For example, the liquid flows from the inlet to the outlet, or the pressure oil flows to the motor in different directions.

Detailed parameters

It is made of high-strength aluminum alloy, cast iron or steel, and has undergone precision machining and surface treatment to ensure its pressure resistance and corrosion resistance.The manufacturing process includes CNC machining, drilling, milling, polishing, etc. to ensure that the flow channel inside the valve block is smooth and reduce the flow resistance of hydraulic fluid.

Product application

Product Line

Our Warehouse

Packing and Transportation

Related News

Submitted successfully

We will contact you as soon as possible