Four-in-one Solenoid Valve

1.High efficiency and reliability:

advanced manufacturing technology, high-quality materials, reduce equipment downtime.

2.Multifunctional design:

multiple control methods, modular design, easy installation and maintenance.

3.Fast response:

short response time, suitable for high dynamic performance requirements.

4.Widely applicable:

suitable for various voltages, high protection level, suitable for harsh environments.

5.Quality service: provide detailed technical support and professional after-sales service.

Detailed parameters

| Maximum working pressure | Maximum decompression pressure | Rated flow rate | Proportional valve | Maximum current | Protection level | Allowable pollution | Switch valve | Allowable ambient operating temperature | The oil temperature range |

| 50 bar | 30 bar | 10L/min | Rated voltage: 24V, connector DT04-2 P | 750mA, resistance: 20.8 Ω±5% | IP6k6/IPX9K | ISO 4406 class 20/18/15 | Voltage range DC27V±15%, plug DTO4-2P, protection level IP67; | -20-80℃ | -20-90℃ |

It is mainly composed of valve body, valve, electromagnet, etc.Among them, the valve is the most critical part of the quadruple solenoid valve. It is composed of a valve core, a valve seat and a spring. Under different working conditions, the valve can withstand different pressure differences and achieve different control purposes.

There are generally two types: direct control and indirect control.Direct control refers to the control of the opening and closing of the valve through electrical signals, while indirect control refers to the control of the solenoid valve through other components such as timer, sensor, etc.A variety of complex control functions can be realized by using indirect control.

It is widely used in various automation equipment, such as organic chemical industry, petroleum, metallurgy, textile, food and other industries.It can realize the control of gases and liquids, so as to achieve various automation control purposes.In the future, with the continuous improvement of the level of industrial automation, the application of quadruple solenoid valves will be more extensive.

Product scenario application

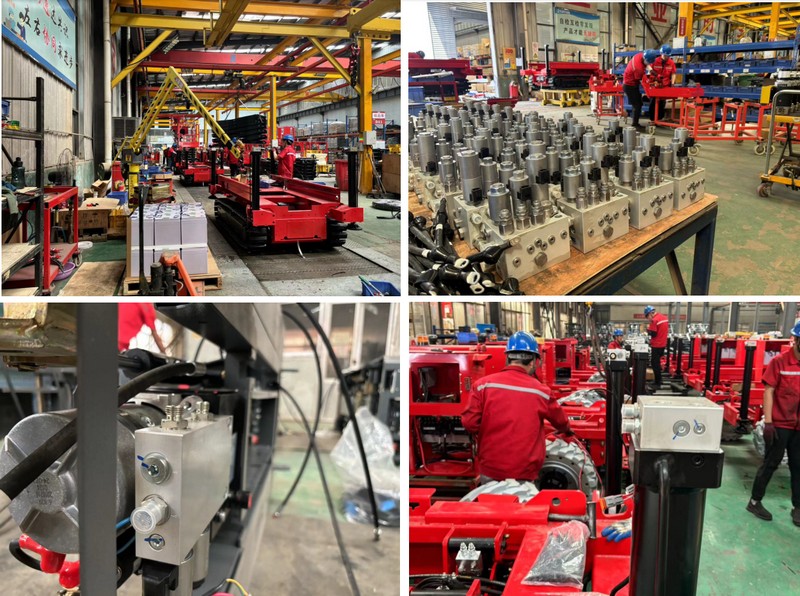

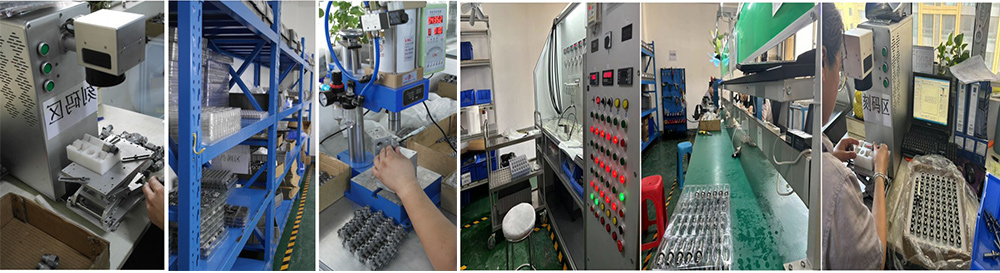

Product Line:

The production line for Customised Hydraulic Valve Blocks is characterised by precise craftsmanship and efficient processes, ensuring that each block is perfectly tailored to the customer's individual requirements. The production line begins with the initial design, which is planned in detail by engineers according to the customer's requirements, followed by material processing and precision manufacturing on high-precision machinery and equipment. After a rigorous assembly and testing process, each valve block is strictly inspected to ensure its performance and durability.

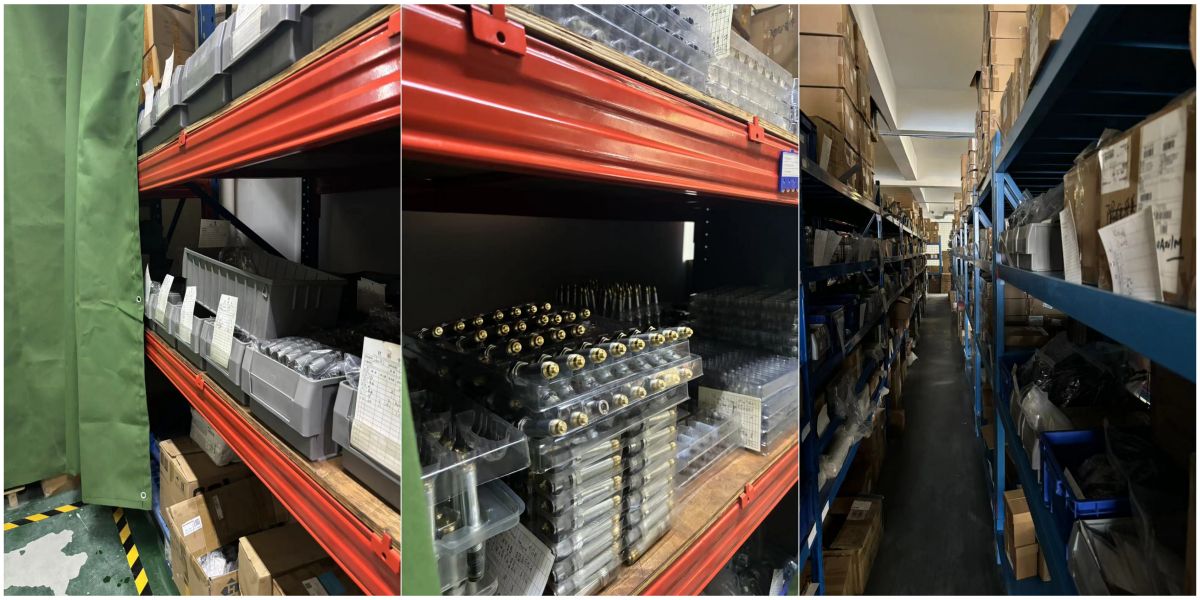

Warehouse:

The facility for producing Customized Hydraulic Valve Blocks is a state-of-the-art manufacturing plant designed for precision and efficiency. The plant features advanced CNC machining centers that ensure high accuracy in cutting, drilling, and milling. Dedicated design and engineering teams work closely to tailor each valve block to meet specific client requirements. The production process includes rigorous assembly and testing stations, where each valve block undergoes thorough quality checks to ensure optimal performance and reliability. The facility also incorporates modern surface treatment and packaging areas, ensuring that the final products are well-protected and ready for prompt delivery to clients.

Packing&transportation:

The packaging for Customized Hydraulic Valve Blocks is meticulously designed to ensure safe and secure transport. Each valve block is carefully wrapped in protective materials, such as foam or bubble wrap, to guard against potential damage during shipping. The blocks are then placed in custom-sized, reinforced boxes that provide additional cushioning and support. Each package is clearly labeled with handling instructions and product information to facilitate smooth logistics and tracking. This comprehensive packaging approach ensures that the valve blocks arrive at their destination in excellent condition, ready for installation and use.