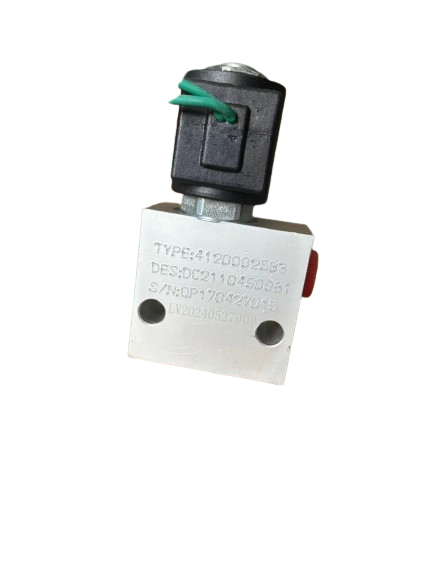

Customized Solenoid Valve

Customized case:

It is small in size, low in power, and has a high upper limit of fluid pressure range. It can be installed at will (customization required), but the fluid differential pressure conditions must be met.

There is a closed cavity inside the solenoid valve, with through holes in different locations, and each hole is connected to a different oil pipe.In the middle of the cavity is a piston, and on both sides are electromagnets. The movement of the valve body is controlled by controlling the current of the electromagnet on and off, thereby opening or closing different oil discharge holes.Hydraulic oil will enter different oil drain pipes, and the pressure of the oil will push the piston of the cylinder, which in turn will drive the piston rod and the mechanical device to move.

Please leave a message or send an email for details to ensure that you are satisfied with the price

1. The external leakage is blocked, the internal leakage is easy to control, and it is safe to use.

Internal and external leakage is an element that endangers safety.Other automatic control valves usually extend the stem, and the rotation or movement of the spool is controlled by electric, pneumatic, and hydraulic actuators.This must solve the problem of leakage caused by the long-term dynamic sealing of the valve stem; only the solenoid valve is completed by electromagnetic force acting on the iron core sealed in the magnetic isolation sleeve of the electric regulating valve. There is no dynamic seal, so the leakage is easy to block.The torque control of the electric valve is not easy, and it is prone to internal leakage, and even the stem head is pulled off; the structure type of the solenoid valve is easy to control internal leakage until it drops to zero.Therefore, solenoid valves are particularly safe to use, especially for corrosive, toxic or high and low temperature media.

2. The system is simple, it can be connected to a computer, and the price is low.

The solenoid valve itself has a simple structure and a low price, which is easier to install and maintain than other types of actuators such as regulating valves.What is more remarkable is that the automatic control system composed of it is much simpler and the price is much lower.Since the solenoid valve is controlled by a switching signal, it is very convenient to connect to an industrial control computer.In today's era of the popularity of computers and a sharp decline in prices, the advantages of solenoid valves are even more obvious.

3. Fast action, small power and lightweight appearance

The response time of the solenoid valve can be as short as a few milliseconds, and even the pilot solenoid valve can be controlled within tens of milliseconds.Due to the self-contained circuit, it is more responsive than other automatic control valves.A properly designed solenoid valve coil has very low power consumption and is an energy-saving product; it can also be used to automatically maintain the valve position by triggering the action, and it usually consumes no power at all.The solenoid valve has a small size, which not only saves space, but also is lightweight and beautiful.

Application Scenarios:

Our customized hydraulic valve blocks represent the top level of hydraulic control technology, designed with a focus on performance, reliability and durability. Their wide range of application scenarios make them ideal for use in a variety of mechanical equipment and industrial systems.

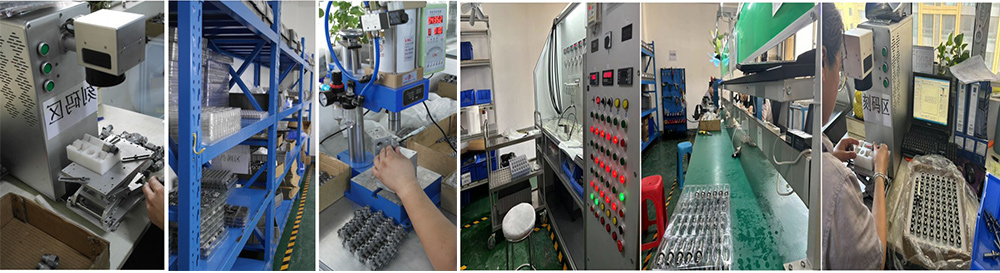

Product Line:

The production line for Customised Hydraulic Valve Blocks is characterised by precise craftsmanship and efficient processes, ensuring that each block is perfectly tailored to the customer's individual requirements. The production line begins with the initial design, which is planned in detail by engineers according to the customer's requirements, followed by material processing and precision manufacturing on high-precision machinery and equipment. After a rigorous assembly and testing process, each valve block is strictly inspected to ensure its performance and durability.

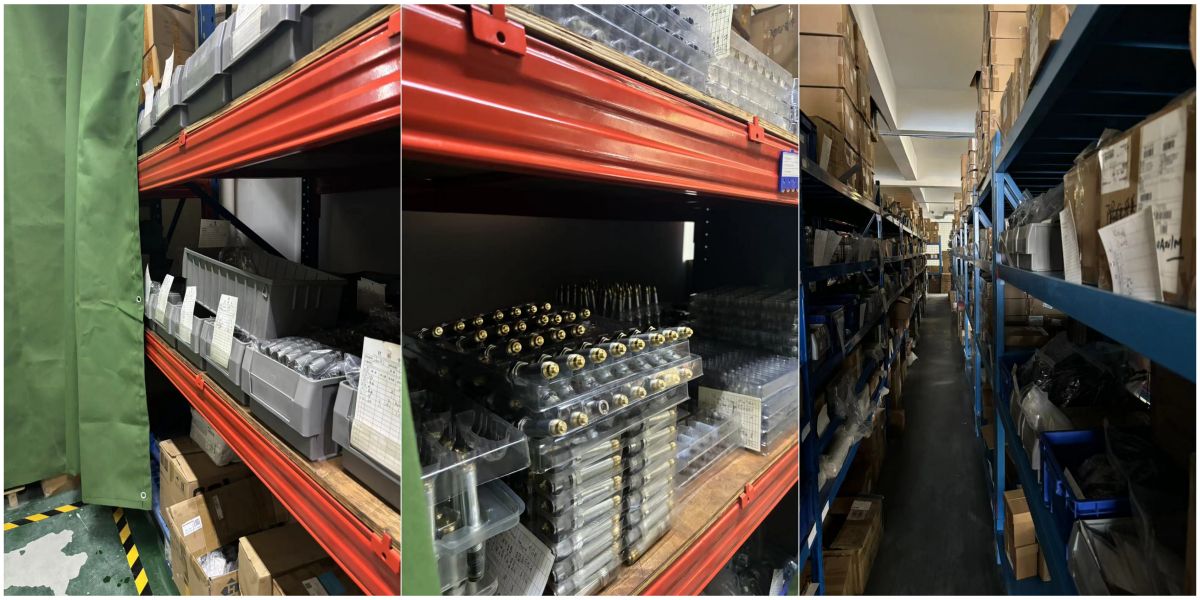

Warehouse:

The facility for producing Customized Hydraulic Valve Blocks is a state-of-the-art manufacturing plant designed for precision and efficiency. The plant features advanced CNC machining centers that ensure high accuracy in cutting, drilling, and milling. Dedicated design and engineering teams work closely to tailor each valve block to meet specific client requirements. The production process includes rigorous assembly and testing stations, where each valve block undergoes thorough quality checks to ensure optimal performance and reliability. The facility also incorporates modern surface treatment and packaging areas, ensuring that the final products are well-protected and ready for prompt delivery to clients.

Packing&transportation:

The packaging for Customized Hydraulic Valve Blocks is meticulously designed to ensure safe and secure transport. Each valve block is carefully wrapped in protective materials, such as foam or bubble wrap, to guard against potential damage during shipping. The blocks are then placed in custom-sized, reinforced boxes that provide additional cushioning and support. Each package is clearly labeled with handling instructions and product information to facilitate smooth logistics and tracking. This comprehensive packaging approach ensures that the valve blocks arrive at their destination in excellent condition, ready for installation and use.

Related News

Submitted successfully

We will contact you as soon as possible