Pilot Oil Source Valve

Customized case:

Allowable working ambient temperature: -30 C-90 C,

Working oil temperature range: -30 C-85 C;

Electromagnet voltage: DC14V±15%,

Solenoid valve power consumption (Watts)=22W;

Accumulator volume 0.5L, precharge pressure 15bar;

Relief valve SRVD pressure is set at 45bar@20L/min;

The pressure of the pressure reducing valve DR08 is set at 35bar@20L/min.

Please leave a message or send an email for details to ensure that you are satisfied with the price

Pilot valve is a kind of control element commonly used in hydraulic systems and is widely used in various mechanical equipment in hydraulic systems.Its main role is to control the action and stop of downstream components through a certain logical relationship in the hydraulic system.

principle

The working principle of the pilot valve is mainly to control the opening and closing of the valve through the pressure transfer and force balance in the hydraulic pressure.When the hydraulic pressure in the system flows to the pilot valve, the spring valve inside the pilot valve will be subjected to the force of hydraulic pressure, which in turn causes the piston at the bottom to rise, thereby opening the hole in the upper chamber, realizing the opening of the valve, allowing the hydraulic pressure to flow to the downstream components.

When the hydraulic pressure no longer enters the pilot valve, due to the pressure of the downstream components, the spring valve inside the pilot valve will bounce back to its original position and move the bottom piston down, causing the hole in the upper chamber to be closed, and the valve will also be closed, stopping the hydraulic flow to the downstream components.

advantages

The pilot valve adopts advanced pressure control technology, which has the advantages of flexible control and high reliability, and can realize precise control and flow adjustment of hydraulic flow, thus providing a high degree of guarantee for the operation of machinery and equipment.At the same time, the pilot valve can also ensure the safety and reliability of the system in high-speed movement, which provides a guarantee for the long-term operation of machinery and equipment.

Frequently asked questions

1. Which machinery and equipment can pilot valves be used in?

Answer: Pilot valves are widely used in various hydraulic machinery and equipment, such as presses, hydraulic jacking machines, hydraulic machine tools, casting machinery, etc.

2. What is the flow adjustment range of the pilot valve?

Answer: The flow adjustment range of the pilot valve can be customized according to user needs, and a larger range of flow adjustment control can usually be achieved.

3. Does the pilot valve work produce noise?

Answer: During the work of the pilot valve, due to the internal pressure transfer and force balance, a certain amount of noise will be generated, but the noise is small and will not affect the operation of machinery and equipment.

The pilot valve has the characteristics of flexible control and high reliability. It is an indispensable control element in hydraulic machinery and equipment, which provides a high degree of guarantee for the operation of machinery and equipment.

Oil source solenoid valves are also widely used in other fields, such as metallurgy, shipbuilding, automobiles and water conservancy.

As a commonly used control equipment, it is widely used in hydraulic systems, pneumatic systems and other automation control fields.This article introduces in detail the working principle, types and application fields of oil source solenoid valves

Application Scenarios:

Our customized hydraulic valve blocks represent the top level of hydraulic control technology, designed with a focus on performance, reliability and durability. Their wide range of application scenarios make them ideal for use in a variety of mechanical equipment and industrial systems.

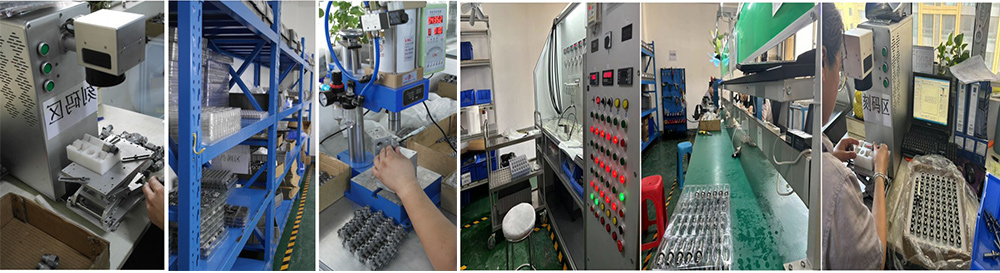

Product Line:

The production line for Customised Hydraulic Valve Blocks is characterised by precise craftsmanship and efficient processes, ensuring that each block is perfectly tailored to the customer's individual requirements. The production line begins with the initial design, which is planned in detail by engineers according to the customer's requirements, followed by material processing and precision manufacturing on high-precision machinery and equipment. After a rigorous assembly and testing process, each valve block is strictly inspected to ensure its performance and durability.

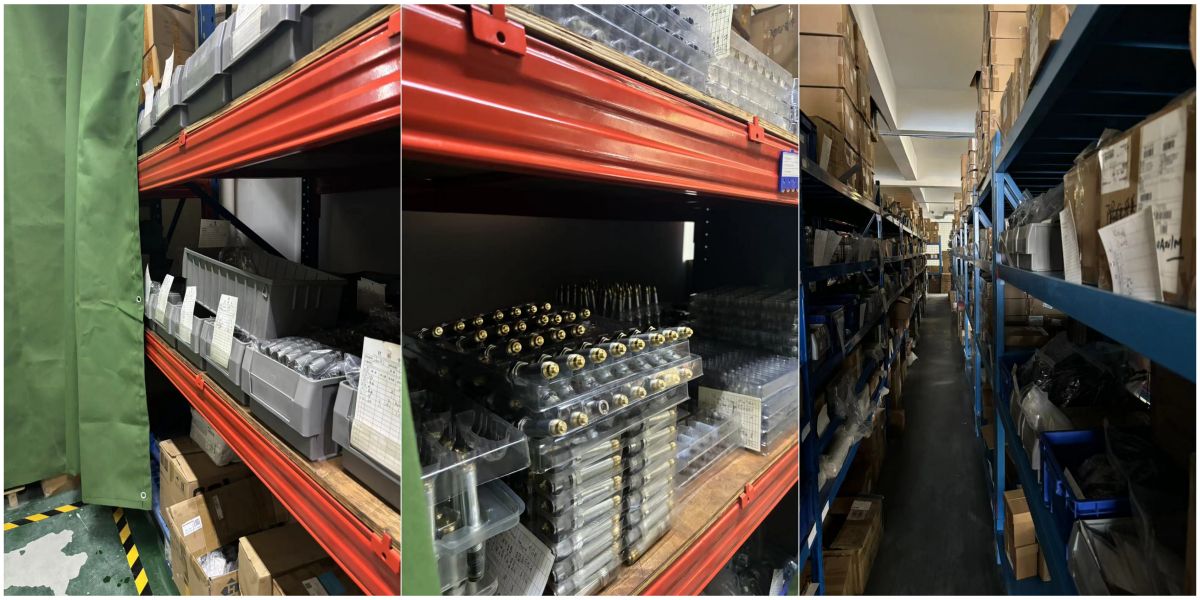

Warehouse:

The facility for producing Customized Hydraulic Valve Blocks is a state-of-the-art manufacturing plant designed for precision and efficiency. The plant features advanced CNC machining centers that ensure high accuracy in cutting, drilling, and milling. Dedicated design and engineering teams work closely to tailor each valve block to meet specific client requirements. The production process includes rigorous assembly and testing stations, where each valve block undergoes thorough quality checks to ensure optimal performance and reliability. The facility also incorporates modern surface treatment and packaging areas, ensuring that the final products are well-protected and ready for prompt delivery to clients.

Packing&transportation:

The packaging for Customized Hydraulic Valve Blocks is meticulously designed to ensure safe and secure transport. Each valve block is carefully wrapped in protective materials, such as foam or bubble wrap, to guard against potential damage during shipping. The blocks are then placed in custom-sized, reinforced boxes that provide additional cushioning and support. Each package is clearly labeled with handling instructions and product information to facilitate smooth logistics and tracking. This comprehensive packaging approach ensures that the valve blocks arrive at their destination in excellent condition, ready for installation and use.