Bypass Valve

1 High-precision control: The hydraulic valve block is precisely designed to provide high-precision flow and pressure control to ensure stable and efficient system operation.

2 Strong reliability: Using high-quality materials and advanced manufacturing technology, the hydraulic valve block has good wear resistance and corrosion resistance, and can operate stably for a long time in harsh environments.

3 Compact design: Hydraulic valve blocks usually have a compact design and take up little space, which is conducive to the integration and installation of the system, especially suitable for applications with limited space.

4 Versatility: A hydraulic valve block can integrate multiple functions, such as adjusting pressure, controlling flow, reversing, etc., to simplify the design and maintenance of the hydraulic system.

5 Easy maintenance: The modular design of the hydraulic valve block makes it more convenient to maintain and replace parts, reduces equipment downtime and improves production efficiency.

Product customization display (hydraulic valves types)

A bypass valve is a control valve used to control the flow and pressure of fluid in a pipeline.Its structure is relatively simple, usually composed of valve body, valve core, spring, etc.When the valve core is under pressure, it will move to a specific position, thereby changing the size of the channel in the valve, thereby adjusting the flow and pressure.

Main functions

1. Control flow: The most important function of the bypass valve is to regulate the flow of fluid. It can direct part of the fluid to the bypass to ensure stable flow in the pipeline.

2. Adjust the pressure: The bypass valve can also be used to adjust the pressure in the pipeline.When the pressure in the pipeline is too high, the valve core automatically closes, reducing the amount of fluid in the pipeline, thereby reducing the pressure.

3. Prevent pipeline explosion: In some important occasions, it is necessary to divert fluid into different pipelines. In some cases, if the flow in the pipeline is too large, it can easily cause the pipeline to explode.The use of bypass valves can effectively prevent pipeline explosions.

4. Reduce noise: In some occasions where it is necessary to keep quiet, such as hospitals and schools, the use of bypass valves can effectively reduce the noise of the fluid in the pipeline and ensure the quiet environment.

Application scenario

1. Industrial pipelines: Bypass valves are often used in industrial pipelines, such as oil refining, chemical industry and other places.It can control the flow and pressure of the fluid in the pipeline, thereby maintaining the stability of the production environment.

2. Fire-fighting system: The bypass valve plays an important role in the fire-fighting system. It can quickly distribute the water flow in the pipeline to different pipelines after a fire, ensuring the efficiency and safety of fire-fighting.

3. Automotive hydraulic system: Bypass valves are also widely used in automotive hydraulic systems, such as brake systems, steering systems, etc.It can control the liquid flow and pressure to ensure the safety and stability of the car.

Bypass valve is a common control valve, mainly used to adjust the flow and pressure of fluid in the pipeline.It has a variety of functions and can be widely used in industrial, fire protection, automotive hydraulic systems and other fields.

Application Scenarios:

Our customized hydraulic valve blocks represent the top level of hydraulic control technology, designed with a focus on performance, reliability and durability. Their wide range of application scenarios make them ideal for use in a variety of mechanical equipment and industrial systems.

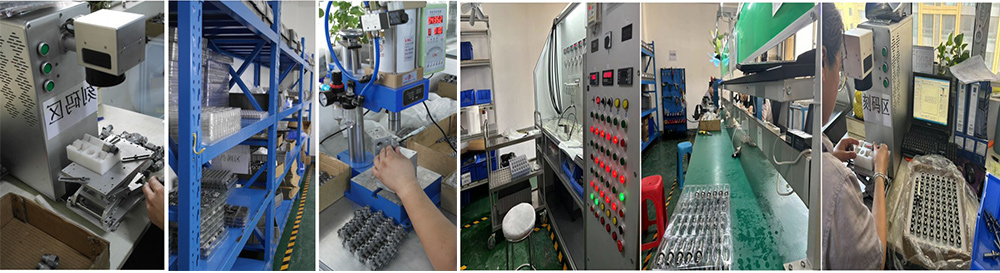

Product Line:

The production line for Customised Hydraulic Valve Blocks is characterised by precise craftsmanship and efficient processes, ensuring that each block is perfectly tailored to the customer's individual requirements. The production line begins with the initial design, which is planned in detail by engineers according to the customer's requirements, followed by material processing and precision manufacturing on high-precision machinery and equipment. After a rigorous assembly and testing process, each valve block is strictly inspected to ensure its performance and durability.

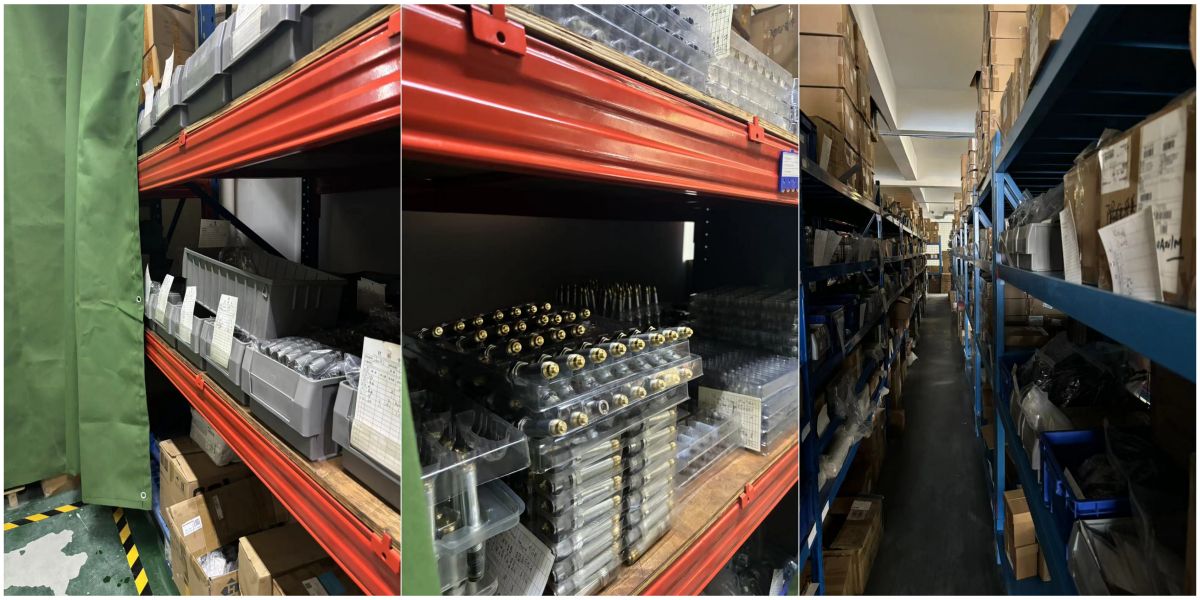

Warehouse:

The facility for producing Customized Hydraulic Valve Blocks is a state-of-the-art manufacturing plant designed for precision and efficiency. The plant features advanced CNC machining centers that ensure high accuracy in cutting, drilling, and milling. Dedicated design and engineering teams work closely to tailor each valve block to meet specific client requirements. The production process includes rigorous assembly and testing stations, where each valve block undergoes thorough quality checks to ensure optimal performance and reliability. The facility also incorporates modern surface treatment and packaging areas, ensuring that the final products are well-protected and ready for prompt delivery to clients.

Packing&transportation:

The packaging for Customized Hydraulic Valve Blocks is meticulously designed to ensure safe and secure transport. Each valve block is carefully wrapped in protective materials, such as foam or bubble wrap, to guard against potential damage during shipping. The blocks are then placed in custom-sized, reinforced boxes that provide additional cushioning and support. Each package is clearly labeled with handling instructions and product information to facilitate smooth logistics and tracking. This comprehensive packaging approach ensures that the valve blocks arrive at their destination in excellent condition, ready for installation and use.