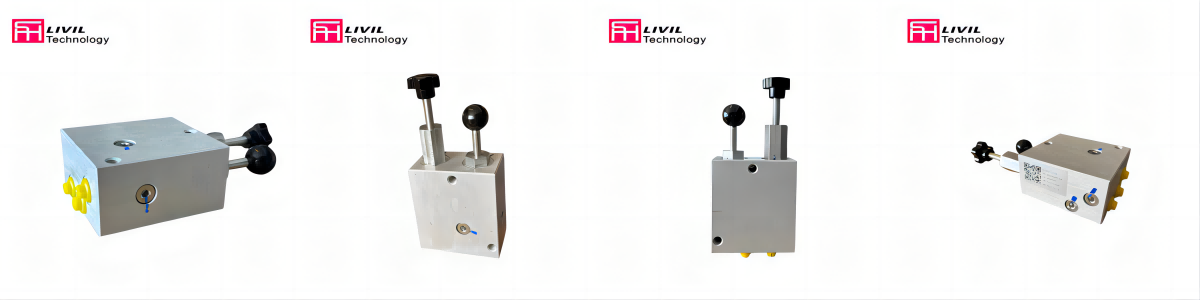

Hand Operated Hydraulic Pump

Maximum Stroke: 29.6

Displacement per Stroke: 2.16cc The valve group can close the main release brake oil circuit when there is no power source

Convert the mechanical energy of power machines (such as electric motors and internal combustion engines) into the pressure energy of liquids

The cam is driven by an electric motor to rotate.When the cam pushes the plunger upward, the sealed volume formed by the plunger and the cylinder body decreases, and the oil is squeezed out of the sealed volume and discharged through the check valve to the desired place. When the cam rotates to the falling part of the curve, the spring forces the plunger down, forming a certain degree of vacuum, and the oil in the tank enters the sealed volume under the action of atmospheric pressure.The cam keeps the plunger rising and falling, the sealing volume decreases and increases periodically, and the pump continuously absorbs and drains oil.

Hand Operated Hydraulic Pump features a maximum stroke of 29.6 and a displacement per stroke of 2.16cc. It includes a valve group that can close the main release brake oil circuit when there is no power source, allowing the brake release to be pressurized through the manual pump, facilitating machine transfer. The valve group can close the main release brake oil circuit when there is no power source, pressurizing the brake release through the manual pump to achieve the transfer of the machine.

Principle of the manual pump

The principle of manual pump is to use manpower (or power, such as foot force or mechanical force) to rotate through the lever and compress the spring or gas inside the pump body to generate pressure, so that the liquid or gas is drawn out or pressed from the pump. The structure of the manual pump is relatively simple, including the pump body, connecting rod, handle rod, valve, gasket and other components. Manual pumps are suitable for a wide variety of liquids and gases, including water, oil, paint, chemicals, air, nitrogen, etc.

Classification of the manual pump

Manual pumps can be divided into the following categories, according to their different usage methods and materials:

1. Hand hydraulic pump: suitable for the transfer and spraying of car paint, paint, acid resistant and alkali resistant fluids.

2. Manual water absorber pump: suitable for pumping, pumping, pipetting, etc.

3. Manual blower: suitable for air inflation and exhaust.

4. Manual fire extinguishing pump: suitable for small area fire extinguishing and environmental rescue.

5. There are also many choices of manual pump materials, such as stainless steel, copper, aluminum and so on, etc.

Manual pump is a very practical mechanical pump, suitable for the transfer and extraction of liquid or gas in various special environments, and has the advantages of simple structure, easy to maintain, easy to use and so on.

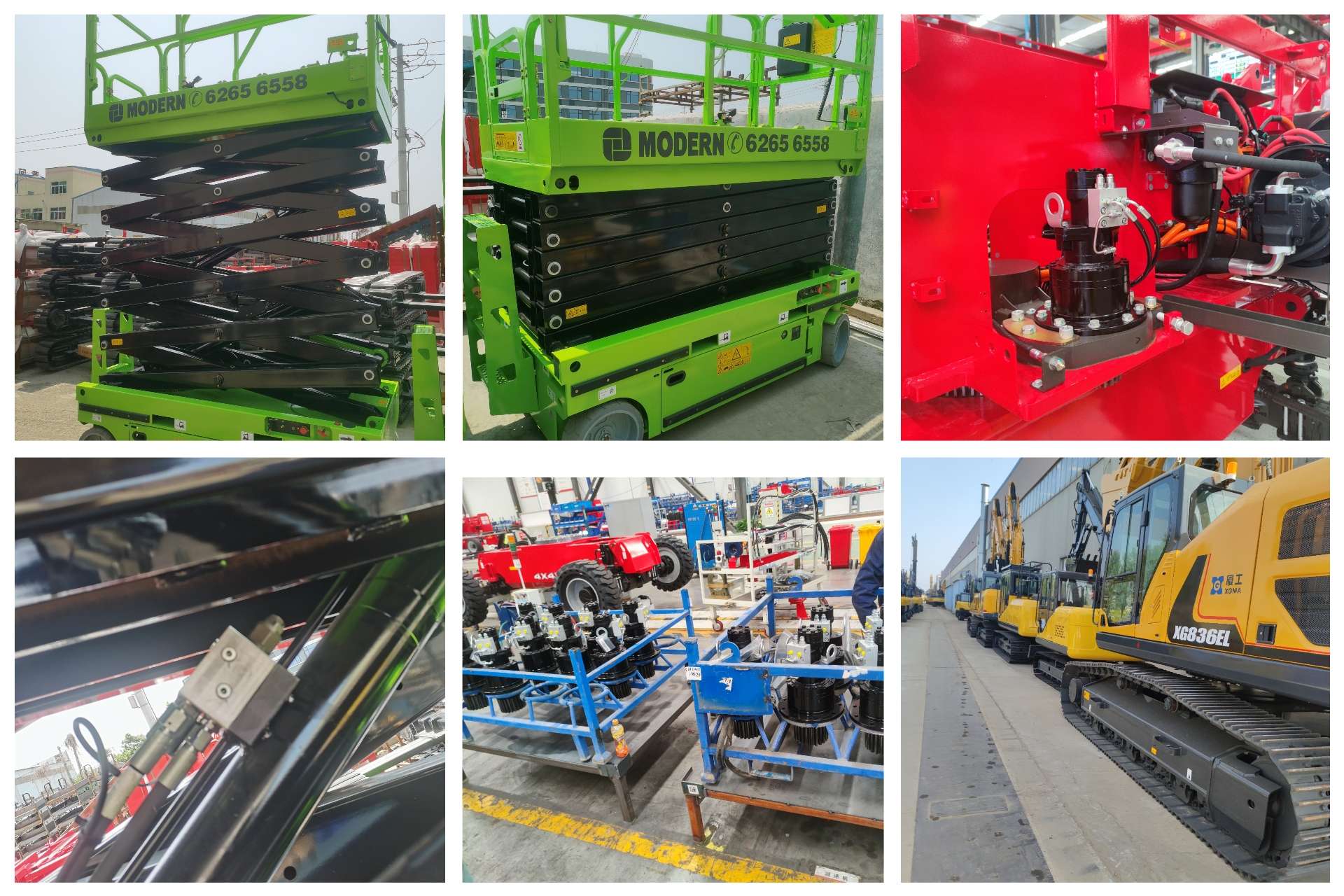

Application

1. Emergency situation. When the power supply is interrupted or the power supply is unstable, the manual pump can be used as a backup option.

2. Areas without a power supply. For example, in the field, ships, vehicles, and unmanned areas, manual pumps can provide a reliable means of transferring and extracting liquid or gas.

3 Environments that require precise control. With precise transfer flow control or a specified amount of liquid or gas extraction, a manual pump can achieve this goal better than the electric pump.

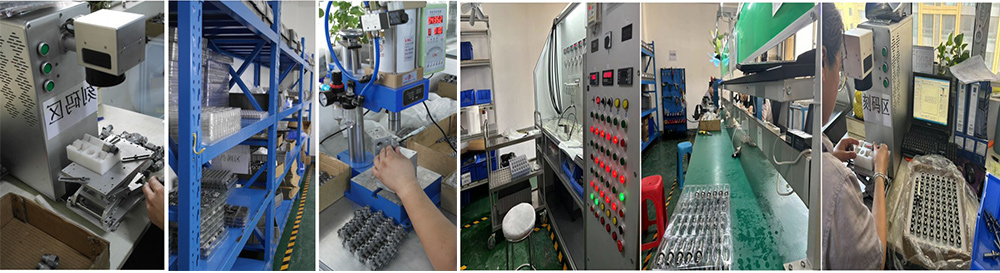

Product Line:

The production line for Customised Hydraulic Valve Blocks is characterised by precise craftsmanship and efficient processes, ensuring that each block is perfectly tailored to the customer's individual requirements. The production line begins with the initial design, which is planned in detail by engineers according to the customer's requirements, followed by material processing and precision manufacturing on high-precision machinery and equipment. After a rigorous assembly and testing process, each valve block is strictly inspected to ensure its performance and durability.

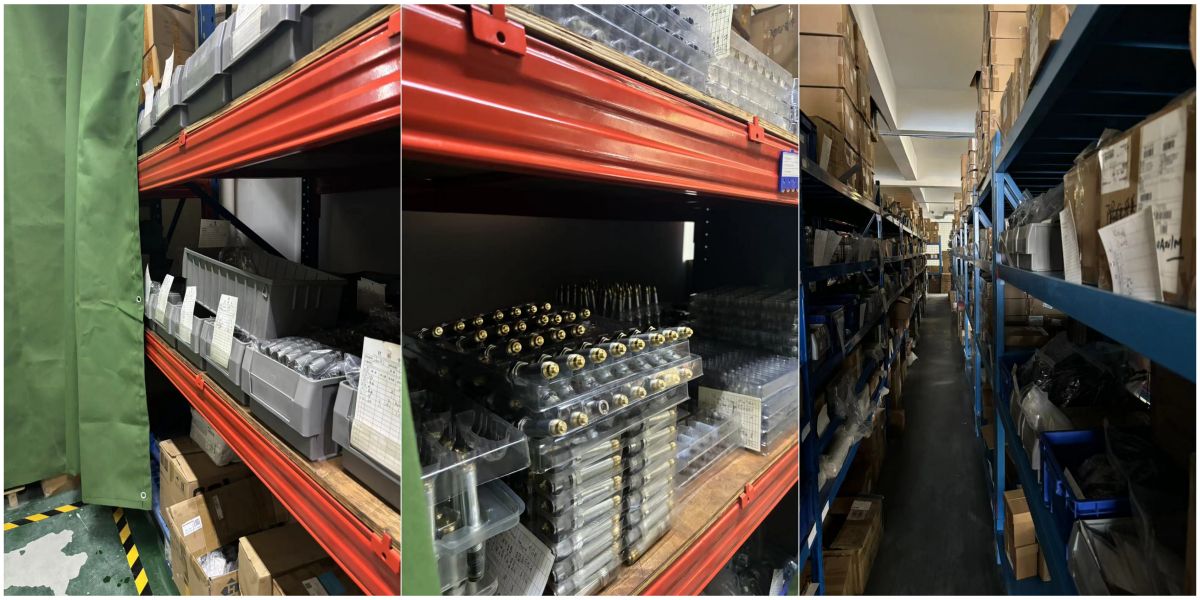

Warehouse:

The facility for producing Customized Hydraulic Valve Blocks is a state-of-the-art manufacturing plant designed for precision and efficiency. The plant features advanced CNC machining centers that ensure high accuracy in cutting, drilling, and milling. Dedicated design and engineering teams work closely to tailor each valve block to meet specific client requirements. The production process includes rigorous assembly and testing stations, where each valve block undergoes thorough quality checks to ensure optimal performance and reliability. The facility also incorporates modern surface treatment and packaging areas, ensuring that the final products are well-protected and ready for prompt delivery to clients.

Packing&transportation:

The packaging for Customized Hydraulic Valve Blocks is meticulously designed to ensure safe and secure transport. Each valve block is carefully wrapped in protective materials, such as foam or bubble wrap, to guard against potential damage during shipping. The blocks are then placed in custom-sized, reinforced boxes that provide additional cushioning and support. Each package is clearly labeled with handling instructions and product information to facilitate smooth logistics and tracking. This comprehensive packaging approach ensures that the valve blocks arrive at their destination in excellent condition, ready for installation and use.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible