Floating balance valve is an automatic regulating valve, commonly used in piping systems, by automatically adjusting the flow and pressure to maintain the stability of the system, and to prevent the pressure from being too high or too low.It is suitable for various fluid media and piping systems, and can provide reliable flow control and pressure regulation functions for the system.principleThe working principle of the floating balance valve is based on its special design structure.It consists of the main valve body, the valve core and the regulating spring.When the liquid flows into the main

Contact Now

Pilot valve is a kind of control element commonly used in hydraulic systems and is widely used in various mechanical equipment in hydraulic systems.Its main role is to control the action and stop of downstream components through a certain logical relationship in the hydraulic system.principleThe working principle of the pilot valve is mainly to control the opening and closing of the valve through the pressure transfer and force balance in the hydraulic pressure.When the hydraulic pressure in the system flows to the pilot valve, the spring valve inside the pilot valve will be subjected to the f

Contact Now

hydraulic solenoid valveDetailed parametersMaximum working pressureMaximum decompression pressureRated flow rateProportional valveMaximum currentProtection levelAllowable pollutionSwitch valveAllowable ambient operating temperatureThe oil temperature range50 bar30 bar10L/minRated voltage: 24V, connector DT04-2P750mA, resistance: 20.8 Ω±5%IP6k6/IPX9K ISO 4406 class 20/18/15Voltage range DC27V±15%, plug DTO4-2P, protection level IP67;-20-80℃-20-90℃It is mainly composed of valve body, valve, electromagnet, etc.Among them, the valve is the most critical part of the quadruple solenoid valve.

Contact Now

Hydraulic control reversing valve set1. Control the pressure of the hydraulic systemThe hydraulic control valve can change the pressure and stability of the hydraulic system by adjusting the opening size and opening method in the valve core, so as to meet the work needs of different pressure requirements. 2.

Contact Now

Product customization display (hydraulic valves types)A bypass valve is a control valve used to control the flow and pressure of fluid in a pipeline.Its structure is relatively simple, usually composed of valve body, valve core, spring, etc.When the valve core is under pressure, it will move to a specific position, thereby changing the size of the channel in the valve, thereby adjusting the flow and pressure.Main functions1. Control flow: The most important function of the bypass valve is to regulate the flow of fluid.

Contact Now

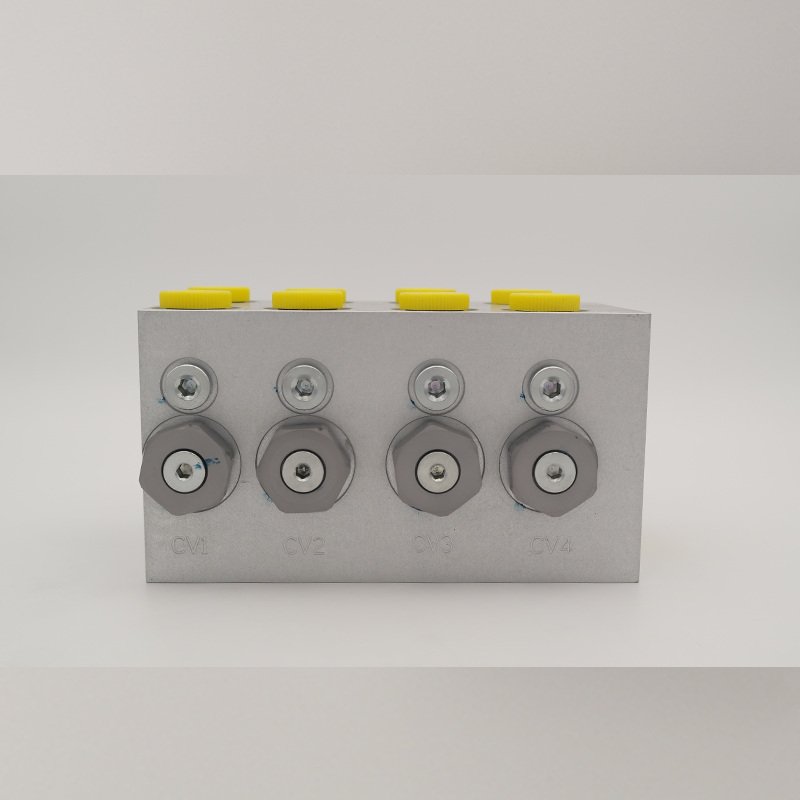

Hydraulic check valveDetailed parametersThe maximum working pressure The opening pressureRated flow250bar4barrate 150 liters/minHydraulic check valveA directional control valve where air flow or liquid can only flow in one direction and cannot flow in reverse.The working principle is a sphere, in a cone.When the liquid passes from one end of the cone to the other, push the sphere away and pass through.When passing in reverse, the sphere clogs the channel and the liquid cannot pass through.Application Scenarios:Our customized hydraulic valve blocks represent the top level of hydraulic control t

Contact Now

Flow Control Valve Parts EC10-42-0-80Pressure compensation valveThreaded cartridge type, priority type, pressure compensation with static load sensing, used to prioritize the required flow rate, while using the remaining flow rate as an auxiliary functionWorking pressure: Oil inlet: 240barMaximum adjustable flow: compensation pressure 5.5 bar: 30.2lpmCompensation pressure: 5.5barTemperature range: -40°C-120°CProduct applicationProduct LineOur WarehousePacking and TransportationPlease leave a message or send an email for details to ensure that you are satisfied with the price

Contact Now

Electronically controlled relief valveIt controls the flow of liquids and is widely used in aviation, chemical industry, shipbuilding, machining and other fields.Its main function is to achieve precise control of liquid flow, direction, pressure and other parameters.The hydraulic control valve can control and adjust the flow rate, pressure and other parameters of the hydraulic system according to different functional requirements, and can cut off the fluid and change the flow direction. The principle is mainly to change the channel of liquid flow through the movement of the valve core, so

Contact Now

The solenoid valve, made from hardened precision parts, provides high flow capacity and efficient hydraulic energy transmission, with all ports capable of full pressure loading. Application1. Application in the field of industrySolenoid valves are widely used in various industrial automation systems, such as transmission line, robot, metallurgy, chemical industry, water conservancy, electric power and other fields.

Contact Now

Flow Control Valve Parts EC42-M42-0-N-80 Pressure compensation valve, threaded cartridge type, priority type, pressure compensation with static load sensingWorking pressure: 241BarMaximum inlet flow: 80gpmMaximum priority flow: pressure 10.3 bar: 55.0gpm Pressure 5.5 bar: 40.0gpmMaximum bypass flow: pressure 10.3 bar: 55.0gpm Pressure 5.5 bar: 40.0gpmTemperature range: -40°C-120°C (standard nitrile rubber seal)Product applicationProduct LineOur WarehousePacking and TransportationPlease leave a

Contact Now

hydraulic pressure reducing valveIt controls the flow of liquids and is widely used in aviation, chemical industry, shipbuilding, machining and other fields.Its main function is to achieve precise control of liquid flow, direction, pressure and other parameters.The hydraulic control valve can control and adjust the flow rate, pressure and other parameters of the hydraulic system according to different functional requirements, and can cut off the fluid and change the flow direction. The principle is mainly to change the channel of liquid flow through the movement of the valve core, so as t

Contact Now

Solenoid reversing valvedirectional valve1. Control the pressure of the hydraulic systemThe hydraulic control valve can change the pressure and stability of the hydraulic system by adjusting the opening size and opening method in the valve core, so as to meet the work needs of different pressure requirements. 2.

Contact Now

hydraulic solenoid valveDetailed parametersRated pressureMaximum flowVoltage range Coil built-in diodeAllowable ambient operating temperatureOil temperature range70bar30L/minDC27V±15%; plug DTO4-2P, Rated power 23.8W, protection level IP67model RL257, Rated reverse voltage 1000V, rated current 2.5A, instantaneous peak current 100A-20-80℃-20-90℃Application Scenarios:Our customized hydraulic valve blocks represent the top level of hydraulic control technology, designed with a focus on performance, reliability and durability.

Contact Now

Hydraulic bypass valveIt controls the flow of liquids and is widely used in aviation, chemical industry, shipbuilding, machining and other fields.Its main function is to achieve precise control of liquid flow, direction, pressure and other parameters.The hydraulic control valve can control and adjust the flow rate, pressure and other parameters of the hydraulic system according to different functional requirements, and can cut off the fluid and change the flow direction. The principle is mainly to change the channel of liquid flow through the movement of the valve core, so as to control t

Contact Now

Electromagnetic reversing valve type B1 High-precision control: The hydraulic valve block is precisely designed to provide high-precision flow and pressure control to ensure stable and efficient system operation.2 Strong reliability: Using high-quality materials and advanced manufacturing technology, the hydraulic valve block has good wear resistance and corrosion resistance, and can operate stably for a long time in harsh environments.3 Compact design: Hydraulic valve blocks usually have a compact design and take up little space, which is conducive to the integration and installation of the s

Contact Now

Hydraulic pilot oil source valve pressure reducing valve1. Control the pressure of the hydraulic systemThe hydraulic control valve can change the pressure and stability of the hydraulic system by adjusting the opening size and opening method in the valve core, so as to meet the work needs of different pressure requirements. 2.

Contact Now

Pilot oil source valve type CDetailed parametersP port pressureMaximum flow rateVoltage rangeRated powerProtection levelAccumulator volumeAllowable ambient working temperatureOil temperature range350bar15L/minDC14V±15%; plug DTO4-2P23.8WIP670.32L, precharge pressure 15bar -20-80℃-20-90℃The interaction between the main valve core and the pilot valve core in the hydraulic system, and the output performance of the hydraulic system is controlled by adjusting the pilot valve.The pilot valve is usually a small-sized control valve, mostly a pressure control valve.

Contact Now

hydraulic pressure relief valveIt controls the flow of liquids and is widely used in aviation, chemical industry, shipbuilding, machining and other fields.Its main function is to achieve precise control of liquid flow, direction, pressure and other parameters.The hydraulic control valve can control and adjust the flow rate, pressure and other parameters of the hydraulic system according to different functional requirements, and can cut off the fluid and change the flow direction. The principle is mainly to change the channel of liquid flow through the movement of the valve core, so as to

Contact Now

Multi-way valveApplication Scenarios:Our customized hydraulic valve blocks represent the top level of hydraulic control technology, designed with a focus on performance, reliability and durability. Their wide range of application scenarios make them ideal for use in a variety of mechanical equipment and industrial systems.Product Line:The production line for Customised Hydraulic Valve Blocks is characterised by precise craftsmanship and efficient processes, ensuring that each block is perfectly tailored to the customer's individual requirements.

Contact Now

hydraulic solenoid valve Structure and flow path diagramTwo-position six-way directional control valve, also known as two-position six-way control valve, its main structure is composed of import and export interface, valve body, valve core, control lever and other parts, wherein the valve body is provided with a corresponding flow channel, used to control the direction of fluid in and out.The flow path diagram is shown below:Among them, A, B, P, and C are the inlet, outlet, internal connection port, and control port respectively.Among them, ports A and B can be connected to different hydraulic

Contact Now

Relief hydraulic valveIt controls the flow of liquids and is widely used in aviation, chemical industry, shipbuilding, machining and other fields.Its main function is to achieve precise control of liquid flow, direction, pressure and other parameters.The hydraulic control valve can control and adjust the flow rate, pressure and other parameters of the hydraulic system according to different functional requirements, and can cut off the fluid and change the flow direction. The principle is mainly to change the channel of liquid flow through the movement of the valve core, so as to control t

Contact Now

Pressure reducing hydraulic valveIt controls the flow of liquids and is widely used in aviation, chemical industry, shipbuilding, machining and other fields.Its main function is to achieve precise control of liquid flow, direction, pressure and other parameters.The hydraulic control valve can control and adjust the flow rate, pressure and other parameters of the hydraulic system according to different functional requirements, and can cut off the fluid and change the flow direction. The principle is mainly to change the channel of liquid flow through the movement of the valve core, so as t

Contact Now

counterbalance valve1. Keep the pressure stableIn a hydraulic system, a hydraulic balance valve can stabilize the hydraulic pressure.Generally speaking, in a hydraulic system, hydraulic actuators with different displacement will cause differences in pressure in the system.If it is not adjusted, some components will be damaged by excessive or small pressure.The hydraulic balance valve can adjust the pressure difference to keep the overall pressure in the hydraulic system stable and prevent the components from being subjected to inappropriate pressure.2.

Contact Now