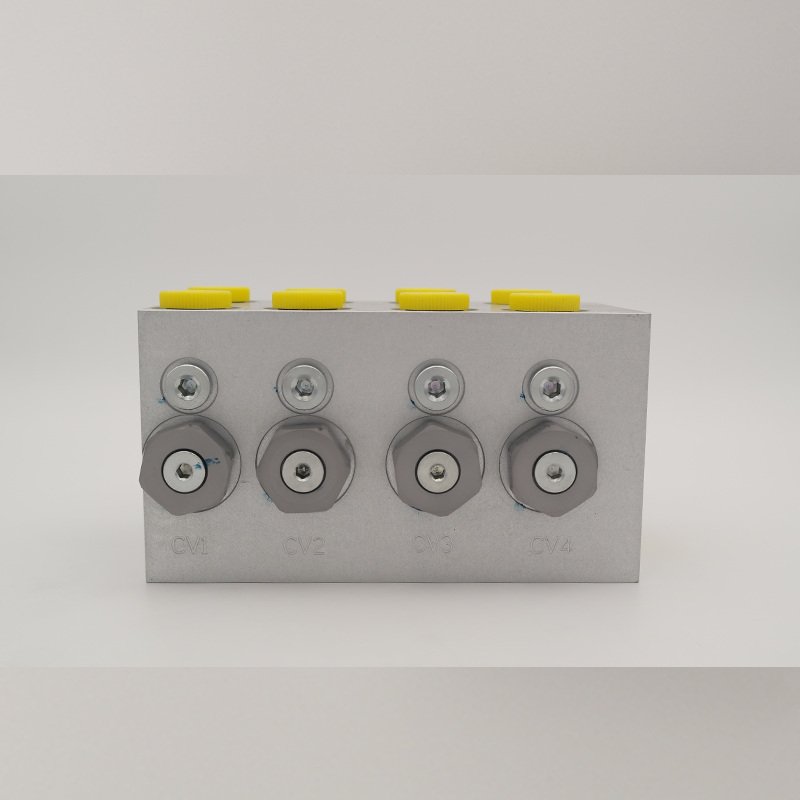

Hydraulic check valveDetailed parametersThe maximum working pressure The opening pressureRated flow250bar4barrate 150 liters/minHydraulic check valveA directional control valve where air flow or liquid can only flow in one direction and cannot flow in reverse.The working principle is a sphere, in a cone.When the liquid passes from one end of the cone to the other, push the sphere away and pass through.When passing in reverse, the sphere clogs the channel and the liquid cannot pass through.Application Scenarios:Our customized hydraulic valve blocks represent the top level of hydraulic control t

Contact Now

The composition and structure of the hydraulic valve blockThe hydraulic valve block is composed of various valves and their accessories, including inlet valves, outlet valves, directional valves, flow valves, pressure valves, check valves, etc.These valves and their accessories are combined to form a hydraulic valve block, which controls the work of the hydraulic system by controlling the flow and pressure of liquid.Working principleThe working principle of the hydraulic valve block is based on the principle of liquid flow control, mainly through the control of valves and accessories to achiev

Contact Now

directional valve Customized hydraulic valve set C020Detailed parametersElectromagnet voltageElectromagnetic coilOil rangeAllowable working ambient temperatureWorking oil temperature rangeDC27±15%protection level IP67HOUSING:174354-2PLATE:174355-7PIN:173706-1RUBBER PLUG:172888-2ISO 10-420Allowable pollution: ISO4406 class21/19/16;-20~80 C-30~90 CParameter:The maximum pressure of the P port 240 barMaximum flow30L/minVoltage rangeDC24V±15%; plug DTO4-2P, rated power 23.8W, protection level IP67Allowable ambient operating temperature-20-80℃The oil temperature range20-90℃Application Scen

Contact Now

Solenoid Reversing Valve Parts SD1E-A2/H2S5-ATwo-position two-way directional control valve, electromagnetic control, cone valve type, no leakage, direct-actingTwo-position two-way high-pressure direct-acting spool valve type threaded cartridge reversing valve.

Contact Now

Solenoid Valve Parts SD4E-A4/H2Y21Two-position four-way directional control valve, electromagnetic control spool valve type, direct-acting high-performance typeMaximum flow rate 30L/minMaximum working pressure 350barOperating ambient temperature range -20°C-80°C、Fluid temperature range -20°C-80°CProduct applicationProduct LineOur WarehousePacking and TransportationPlease leave a message or send an email for details to ensure that you are satisfied with the price

Contact Now

hydraulic solenoid valve Structure and flow path diagramTwo-position six-way directional control valve, also known as two-position six-way control valve, its main structure is composed of import and export interface, valve body, valve core, control lever and other parts, wherein the valve body is provided with a corresponding flow channel, used to control the direction of fluid in and out.The flow path diagram is shown below:Among them, A, B, P, and C are the inlet, outlet, internal connection port, and control port respectively.Among them, ports A and B can be connected to different hydraulic

Contact Now

counterbalance valve1. Keep the pressure stableIn a hydraulic system, a hydraulic balance valve can stabilize the hydraulic pressure.Generally speaking, in a hydraulic system, hydraulic actuators with different displacement will cause differences in pressure in the system.If it is not adjusted, some components will be damaged by excessive or small pressure.The hydraulic balance valve can adjust the pressure difference to keep the overall pressure in the hydraulic system stable and prevent the components from being subjected to inappropriate pressure.2.

Contact Now

Lower lifting hydraulic valveDetailed parametersRated pressureRated flowVoltagematerialopening pressure240bar20L/minDC24V±10%; plug type DTO4-2PValve body material aluminum alloy, surface anodized0.5 barThe hydraulic valve is a key component in the hydraulic system.

Contact Now

Manual descending hydraulic valveParameter:The maximum pressure of the P port 240 barMaximum flow30L/minVoltage rangeDC24V±15%; plug DTO4-2P, rated power 23.8W, protection level IP67Allowable ambient operating temperature-20-80℃The oil temperature range20-90℃Application Scenarios:Our customized hydraulic valve blocks represent the top level of hydraulic control technology, designed with a focus on performance, reliability and durability.

Contact Now

Hydraulic bypass valveIt controls the flow of liquids and is widely used in aviation, chemical industry, shipbuilding, machining and other fields.Its main function is to achieve precise control of liquid flow, direction, pressure and other parameters.The hydraulic control valve can control and adjust the flow rate, pressure and other parameters of the hydraulic system according to different functional requirements, and can cut off the fluid and change the flow direction. The principle is mainly to change the channel of liquid flow through the movement of the valve core, so as to control t

Contact Now

Hydraulic pilot oil source valveDetailed parametersRated working pressureRated flow210 bar20LPMProduct applicationProduct LineOur WarehousePacking and TransportationPlease leave a message or send an email for details to ensure that you are satisfied with the price

Contact Now

hydraulic pressure relief valveIt controls the flow of liquids and is widely used in aviation, chemical industry, shipbuilding, machining and other fields.Its main function is to achieve precise control of liquid flow, direction, pressure and other parameters.The hydraulic control valve can control and adjust the flow rate, pressure and other parameters of the hydraulic system according to different functional requirements, and can cut off the fluid and change the flow direction. The principle is mainly to change the channel of liquid flow through the movement of the valve core, so as to

Contact Now

Pressure reducing hydraulic valveIt controls the flow of liquids and is widely used in aviation, chemical industry, shipbuilding, machining and other fields.Its main function is to achieve precise control of liquid flow, direction, pressure and other parameters.The hydraulic control valve can control and adjust the flow rate, pressure and other parameters of the hydraulic system according to different functional requirements, and can cut off the fluid and change the flow direction. The principle is mainly to change the channel of liquid flow through the movement of the valve core, so as t

Contact Now

Relief hydraulic valveIt controls the flow of liquids and is widely used in aviation, chemical industry, shipbuilding, machining and other fields.Its main function is to achieve precise control of liquid flow, direction, pressure and other parameters.The hydraulic control valve can control and adjust the flow rate, pressure and other parameters of the hydraulic system according to different functional requirements, and can cut off the fluid and change the flow direction. The principle is mainly to change the channel of liquid flow through the movement of the valve core, so as to control t

Contact Now

Two solenoid hydraulic valvesDetailed parametersRated pressureMaximum decompression pressureProportional valve 2 Rated voltageMaximum coil currentCoil resistance at 20℃Optimized PWM frequencySolenoid valve 3 rated voltageAllowable ambient operating temperatureOil temperature range50 bar30 barDC 24V500mA31Ω±5 %600HZ, connector DT04-2PDC24V±10%, connector DT04-2P -20-80℃The working principle of the two-in-one solenoid valve mainly involves the interaction of the electromagnet, the valve body and the valve core, and controls the mechanical movement by controlling the current on and off of the ele

Contact Now

Basic valve block with overflow valve, belongs to fluid control elements, used to control the flow and pressure of fluid in the pipeline.The foundation valve block of the power unit with the overflow valve is a fluid control element used to control the flow and pressure of the fluid in the pip.The hydraulic valve block is composed of various valves and their accessories, including inlet valves, outlet valves, directional valves, flow valves, pressure valves, check valves, etc.These valves and their accessories are combined to form a hydraulic valve block, which controls the work of the hydraul

Contact Now

Hydraulic control reversing valve set1. Control the pressure of the hydraulic systemThe hydraulic control valve can change the pressure and stability of the hydraulic system by adjusting the opening size and opening method in the valve core, so as to meet the work needs of different pressure requirements. 2.

Contact Now

Two-position three-way solenoid hydraulic valveDetailed parameters:Working pressureMaximum flow rateVoltage rangePlug connection modelElectromagnetic coil protection levelSolenoid valve powerCheck valve opening pressureAllowable pollutionAllowable working ambient temperatureOil viscosity range50bar30L/min DC27V±15% DT04-2PIP67<30W1bar, diameter 821/18/15 -30℃--90℃ ISO 20--400mm2/SApplication Scenarios:Our customized hydraulic valve blocks represent the top level of hydraulic control technology, designed with a focus on performance, reliability and durability.

Contact Now

Type 4C hydraulic valve blockIt is an important part of the hydraulic system. It has many functions, including the following points: 1. Control the flow of liquid The hydraulic valve block can control the flow direction of the liquid so that the liquid can flow to the desired part.For example, the flow of pressure oil to the hydraulic cylinder enables it to move, or the flow of liquid to the hydraulic motor enables it to drive mechanical movement. 2.

Contact Now

Customized model of hydraulic valve blockProduct applicationProduct LineOur WarehousePacking and Transportation

Contact Now

Upper lifting hydraulic valveIt controls the flow of liquids and is widely used in aviation, chemical industry, shipbuilding, machining and other fields.Its main function is to achieve precise control of liquid flow, direction, pressure and other parameters.The hydraulic control valve can control and adjust the flow rate, pressure and other parameters of the hydraulic system according to different functional requirements, and can cut off the fluid and change the flow direction. The principle is mainly to change the channel of liquid flow through the movement of the valve core, so as to co

Contact Now

Hydraulic Valve Block Parts385It is an important part of the hydraulic system. It has many functions, including the following points: 1. Control the flow of liquid The hydraulic valve block can control the flow direction of the liquid so that the liquid can flow to the desired part.For example, the flow of pressure oil to the hydraulic cylinder enables it to move, or the flow of liquid to the hydraulic motor enables it to drive mechanical movement. 2.

Contact Now

Customized hydraulic valve block HIC101000332Detailed parametersThe maximum pressure of the P port Maximum flow Voltage rangeAllowable ambient operating temperatureThe oil temperature range 240bar30L/minDC24V±15%; plug DTO4-2P, rated power 23.8W, protection level IP67-20-80℃20-90℃Product applicationProduct LineOur WarehousePacking and TransportationPlease leave a message or send an email for details to ensure that you are satisfied with the price

Contact Now